Polarizer Sheet Overview

In modern life, we’re constantly surrounded by screens—from smartphones to televisions, tablets, and laptops. But did you know? Behind every screen lies an unsung hero: the polarizer. This seemingly unremarkable material is actually the cornerstone of modern display technology.

How Polarizer Sheets Work

Polarizer sheet, formally known as a polarizer film, is a precision optical material. Composed of multiple thin layers, its core function is to control the polarization direction of light. Simply put, it allows light from specific directions to pass through while blocking or redirecting light from other angles. In liquid crystal display (LCD) technology, the role of polarizing film is particularly crucial.

Role of LCD Polarizer Sheets in LCD Displays

Liquid crystal displays (LCDs) themselves do not emit light and rely on an external light source. The polarizer acts as a navigator for light, transforming the chaotic light emitted by the backlight module into orderly polarized light. After being finely regulated by the liquid crystal layer, this light ultimately forms the images we see.

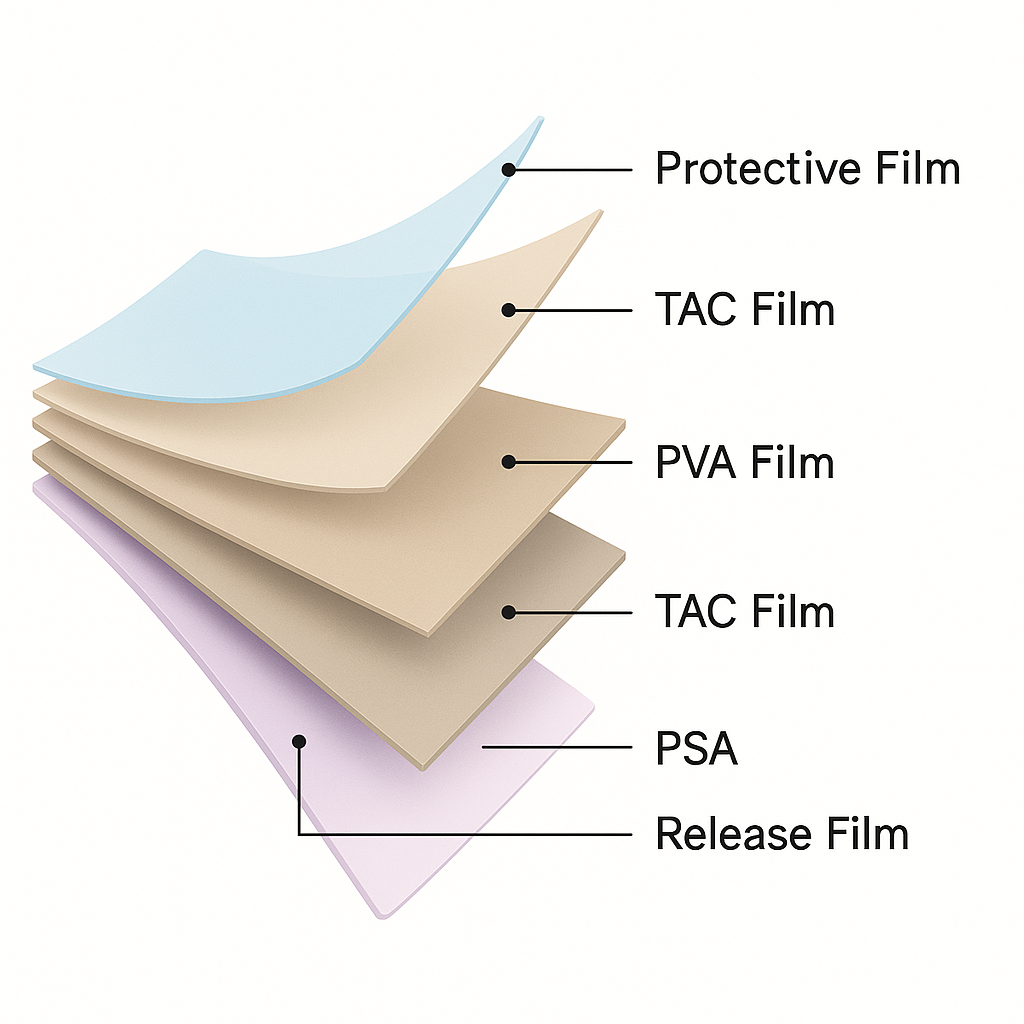

Structure and Materials of LCD Polarizer Sheets

The construction of a polarizer is highly complex, incorporating multiple high-tech materials such as PVA (polyvinyl alcohol) film, TAC (triacetate cellulose) film, pressure-sensitive adhesive, release liner, and protective film. The PVA film is the core component; through stretching and dyeing processes, it gains its unique polarization capability. The TAC film provides structural support and protection while contributing essential optical properties.

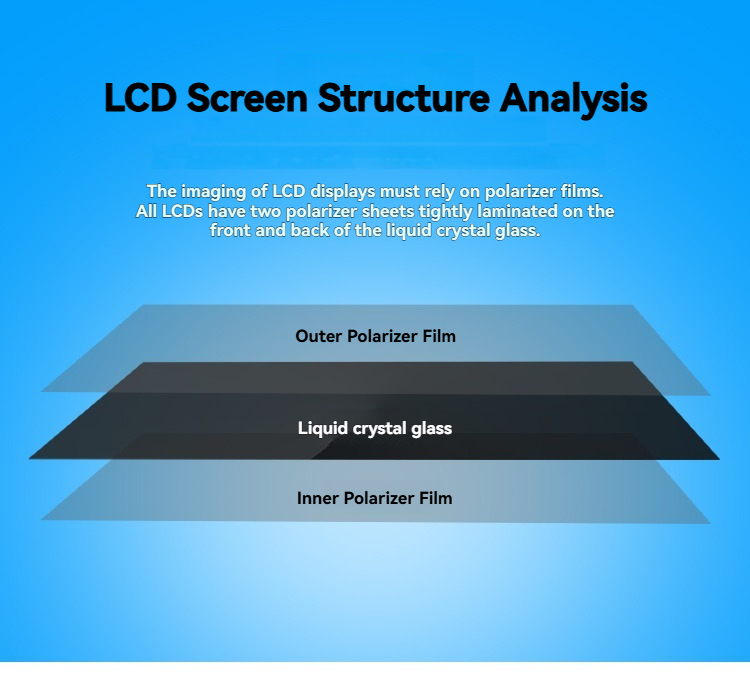

How Two Polarizer Sheets Work Together in LCD Modules

Within LCD modules, polarizers typically appear in pairs, positioned on either side of the liquid crystal panel. The lower polarizer converts backlight into orderly polarized light, while the upper polarizer analyzes light refracted through the liquid crystal layer, ultimately forming the image we perceive. Their seamless coordination determines critical visual metrics like brightness, contrast, and color saturation.

Innovations in Polarizer Sheet Technology

As technology advances, polarizer innovation continues. To meet demands for higher resolution, wider viewing angles, and lower power consumption, manufacturers explore new materials and processes to make polarizers thinner, more efficient, and durable. Examples include ultra-thin film layer designs to minimize light loss, and optimized adhesive formulations and coating techniques to enhance longevity.

The Future of Polarizer Sheets in Displays

In summary, polarizing films shine brightly on the digital stage with their unique polarization properties and exceptional optical performance. As technology continues to advance and application domains expand, we have every reason to anticipate that polarizing film technology will usher in an even more brilliant chapter, guiding us toward a more vibrant and colorful digital future.

Soluciones de fondo de fondo personalizadas & Proveedor de hojas ópticas – Rnoda Tech

Soluciones de fondo de fondo personalizadas & Proveedor de hojas ópticas – Rnoda Tech