1.¿Qué es una placa guía de luz?

Una placa guía de luz utiliza la alta transparencia y las excelentes propiedades refractivas del acrílico (PMMA). En la lámina acrílica de grado óptico, se crean puntos, líneas o patrones grabados con láser en cualquier superficie para alterar el material. Luego se utilizan luces LED para guiar la luz desde el costado, con el brillo y la uniformidad determinados por la densidad y profundidad de las interrupciones.

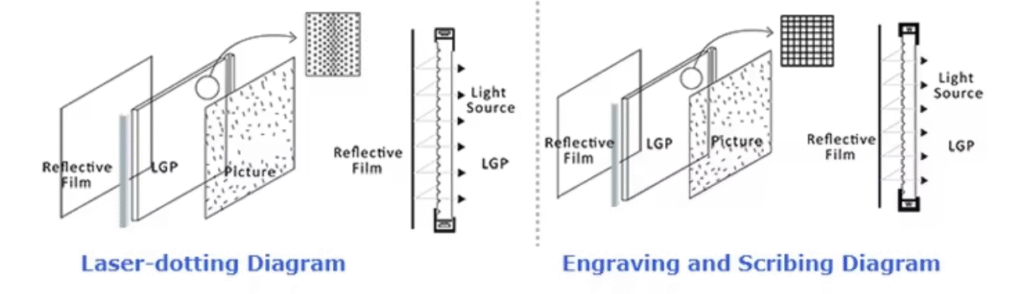

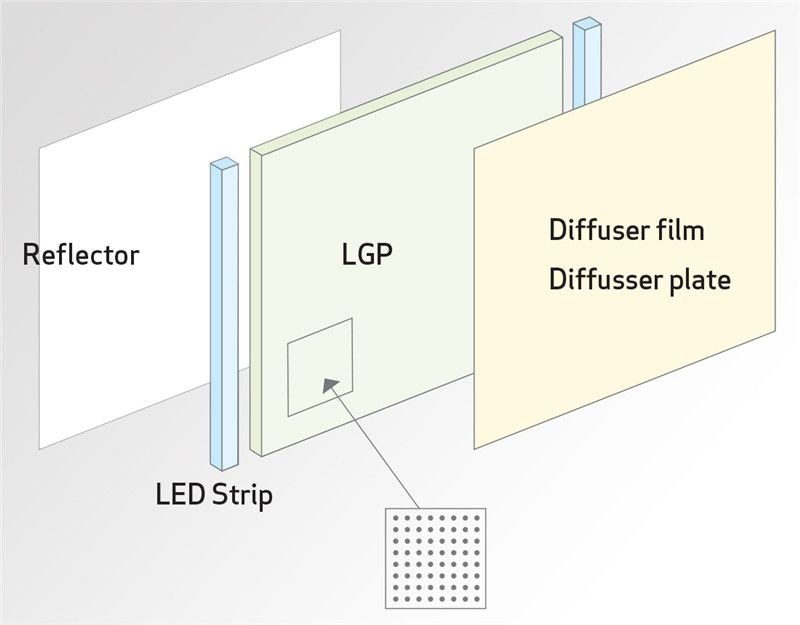

2.Principio de funcionamiento de una placa guía de luz.

Una placa guía de luz (LGP) utiliza láminas de acrílico/PC de grado óptico. Se utilizan materiales de alta tecnología con índices de refracción extremadamente altos y baja absorción de luz para grabar puntos de guía de luz en la superficie inferior de la lámina acrílica de grado óptico mediante grabado láser, grabado de rejilla cruzada en forma de V o tecnología de serigrafía UV. Las láminas acrílicas de grado óptico absorben la luz emitida por la lámpara y la retienen en sus superficies. Cuando la luz incide en los puntos de guía de luz, la luz reflejada se propaga en varias direcciones y la luz se emite desde el frente de la hoja de guía de luz después de que se alteran las condiciones de reflexión. Al utilizar puntos de guía de luz de diferentes densidades y tamaños, la placa de guía de luz puede emitir luz de manera uniforme. El propósito de la lámina reflectante es reflejar la luz expuesta en la superficie inferior de regreso al panel guía de luz, mejorando así la eficiencia de utilización de la luz; bajo la misma área de intensidad luminosa, logra una alta eficiencia luminosa y un bajo consumo de energía. Los LGP de matriz microestructurada de un solo lado se fabrican generalmente mediante un proceso de moldeo por extrusión.

3.Ventajas y desventajas de las placas guía de luz impresas y de las placas guía de luz grabadas con láser

① La placa guía de luz impresa se utiliza generalmente para retroiluminación en pantallas en blanco y negro. Son adecuados para tamaños pequeños donde el brillo y la uniformidad no son críticos. Si bien la superficie puede tener impurezas, estas son muy utilizadas siempre y cuando no afecten la funcionalidad. Por lo general, tienen menos de 2 mm de espesor y no superan los 150 mm de tamaño.

② Las guías de luz grabadas con láser requieren un grosor mínimo de 2 mm y se pueden personalizar con patrones de puntos y niveles de brillo flexibles.

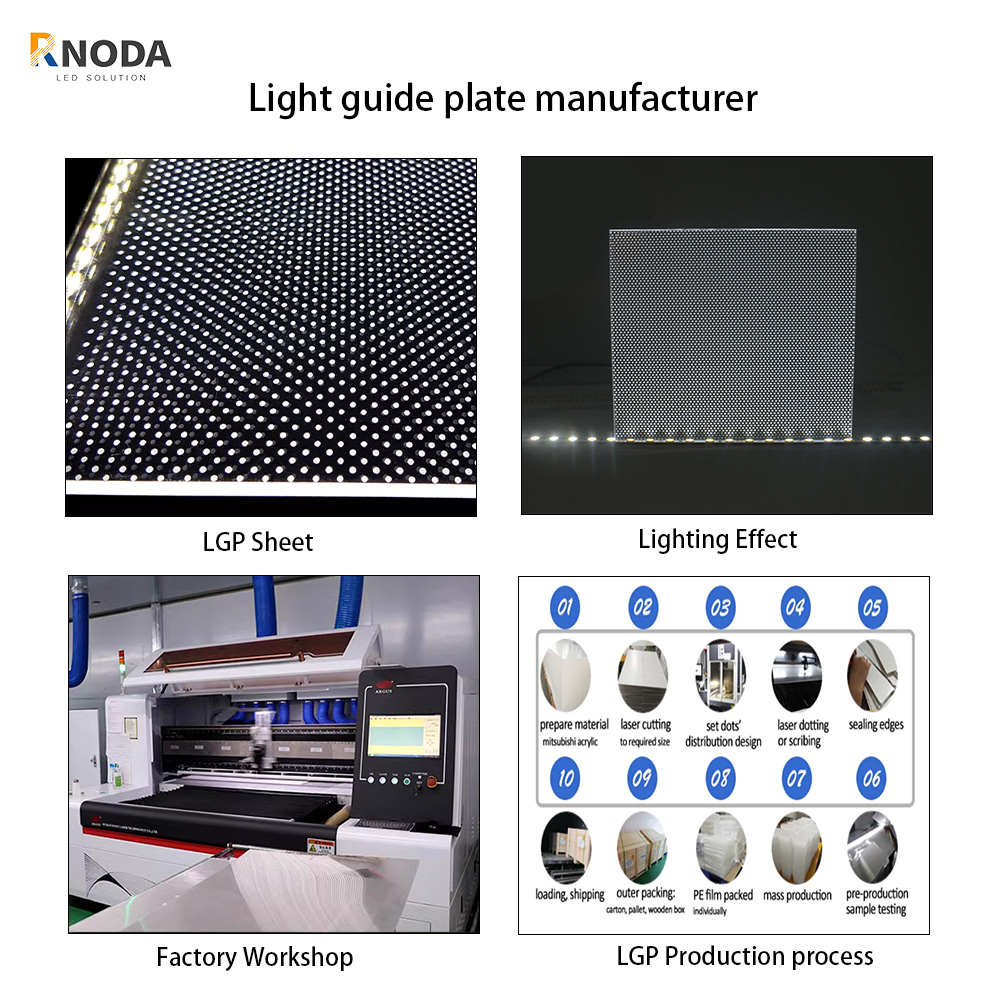

4.Procesos de fabricación de placa guía de luz LGP

Los principales procesos de fabricación de placas guía de luz incluyen los siguientes:

1)LGP de moldeo por inyección

Principio: Los gránulos de PMMA (polimetacrilato de metilo) o PC (policarbonato) se calientan y se funden, luego se inyectan en moldes de precisión para formar la forma deseada. La superficie del molde se graba con microestructuras (como puntos o prismas) y la pieza moldeada se desmolda después del enfriamiento.

Ventajas: Puede formar estructuras complejas en una sola pieza, rendimiento óptico estable, adecuado para producción en masa.

Desventajas: Altos costos de desarrollo de moldes, altos costos de modificación, no apto para lotes pequeños o requisitos personalizados.

2)Procesamiento láser LGP

Principio: utilizar láseres UV/CO₂ para grabar puntos o ranuras de dispersión en la superficie de la placa guía de luz, ajustando la energía y la frecuencia del láser para controlar la densidad y la profundidad de los puntos.

Ventajas: No requiere molde, ajuste rápido de patrones de puntos, alta precisión, adecuado para requisitos personalizados.

Desventajas: Bajo volumen de producción, inadecuado para la producción en masa, mayores costos.

3)LGP de prensado en caliente

Principio: el sustrato de la placa guía de luz se calienta hasta su temperatura de transición vítrea (aproximadamente 105 °C para PMMA), luego se utiliza un molde de metal para imprimir microestructuras en la superficie, que se enfrían y fraguan.

Ventajas: Costos de molde bajos, adecuado para producción de volumen medio, sin desperdicio químico.

Desventajas: El calentamiento/enfriamiento lleva tiempo y la eficiencia de producción es menor que la del moldeo por inyección.

4)Serigrafía LGP

Principio: Se imprimen puntos de resina blancos o transparentes en la parte posterior de la placa guía de luz y la dispersión de la luz se ajusta regulando la densidad de puntos.

Ventajas: Baja inversión en equipamiento.

Desventajas: Tamaño de punto más grande (normalmente >50 μm), poca uniformidad y la tinta puede desprenderse o amarillear.

Diferentes procesos son adecuados para diferentes escenarios. El moldeo por inyección es adecuado para la producción a gran escala, el procesamiento láser para requisitos personalizados, el prensado en caliente para productos ultrafinos de gran tamaño y la serigrafía para un bajo costo pero una precisión limitada. En aplicaciones prácticas, la elección debe hacerse en función de los requisitos del producto, el volumen de producción y el costo.

Importancia del brillo de la placa guía de luz

① Los materiales domésticos suelen tener espesores inconsistentes, lo que da lugar a superficies irregulares. La luz emitida se distorsiona, lo que produce sombras o brillo desigual de aproximadamente el 85%.

② Suponiendo que el material sea de buena calidad, la disposición de los puntos también es fundamental. La densidad de los puntos afecta significativamente al brillo. Por lo tanto, el patrón de puntos se ajusta según los requisitos del cliente y la dirección de la iluminación para lograr resultados óptimos.

③ Las luces LED también son un componente crítico, ya que su brillo y uniformidad de distribución juegan un papel importante. Si el brillo de cada tira de luz es desigual o la potencia es inestable, puede provocar fluctuaciones en el brillo.

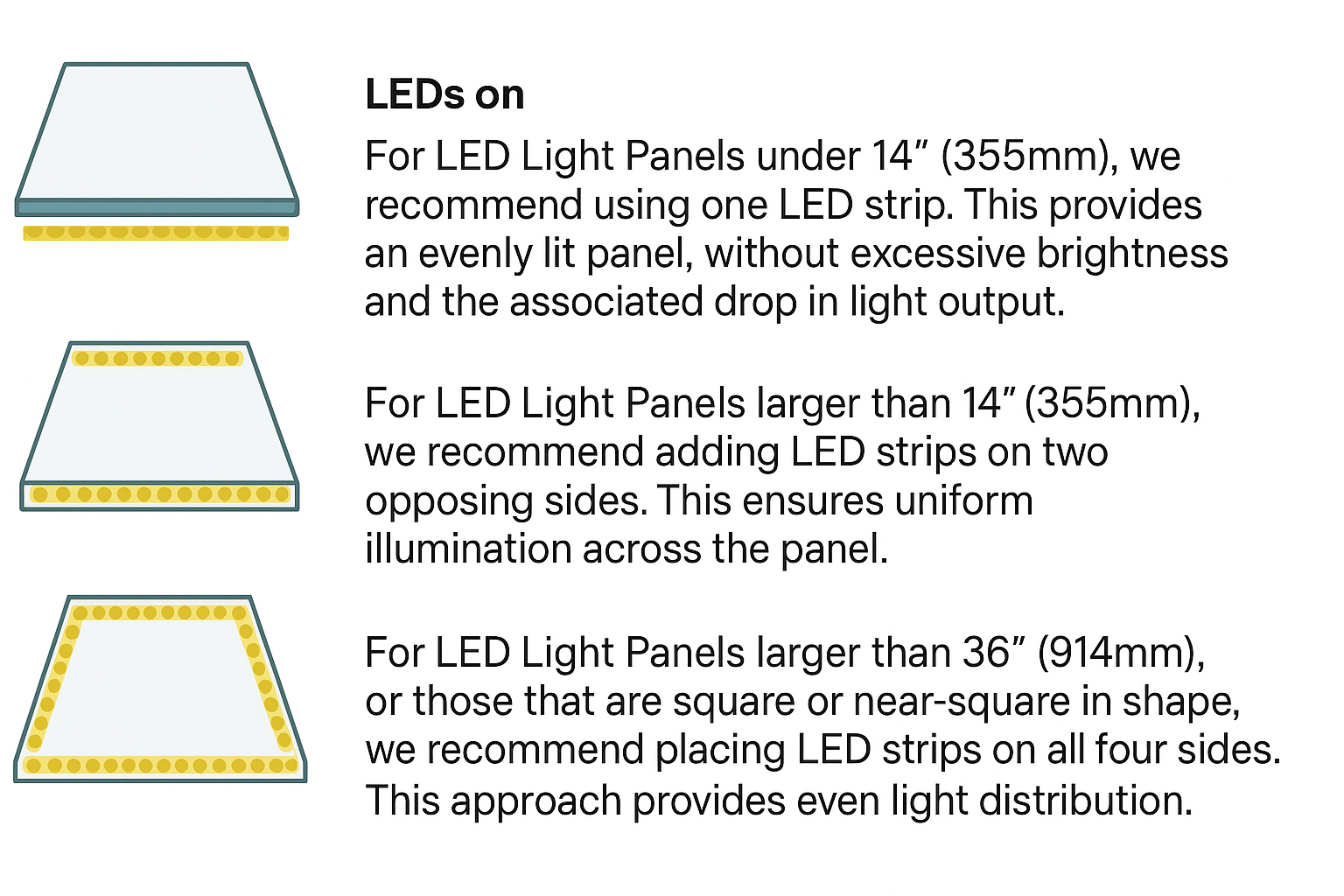

Lados de instalación de la tira de LED según el tamaño de la placa guía de luz

Para paneles de luz LED menores de 14 años″(355 mm), recomendamos utilizar una tira de LED. Esto proporciona un panel iluminado uniformemente, sin brillo excesivo y la caída asociada en la salida de luz.

Para paneles de luz LED de más de 14″(355 mm) recomendamos agregar tiras de LED en dos lados opuestos. Esto garantiza una iluminación uniforme en todo el panel.

Para paneles de luz LED de más de 36″(914 mm), o aquellas que tienen forma cuadrada o casi cuadrada, recomendamos colocar tiras de LED en los cuatro lados. Este enfoque proporciona una distribución uniforme de la luz.

Placas guía de luz personalizadas: adaptadas a sus necesidades

Como fabricante profesional de LGP, ya sea que necesite un tamaño, grosor o forma específicos, podemos fabricar placas guía de luz que se adapten perfectamente a su aplicación, garantizando un ajuste preciso y un rendimiento óptimo.

No espere, comuníquese con nosotros hoy y obtenga su cotización gratuita.

Soluciones de fondo de fondo personalizadas & Proveedor de hojas ópticas – Rnoda Tech

Soluciones de fondo de fondo personalizadas & Proveedor de hojas ópticas – Rnoda Tech