Esistono 2 tipi di pannello a LED: Bordo-illuminato E Retro-illuminato . Qual è la differenza tra loro?

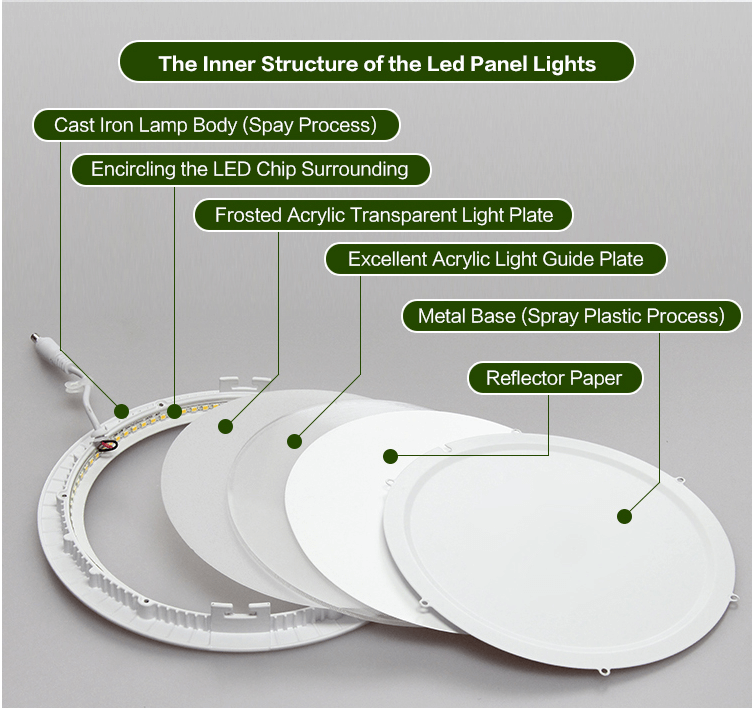

Le luci del pannello a LED sono disponibili in tre categorie di dimensioni principali: una è le luci del pannello di piccole dimensioni, come i downlight, in cui la luce viene emessa da LED montati laterali e trasmessa attraverso una piastra di guida della luce. Sono disponibili in forme quadrate o rotonde, con dimensioni che vanno da circa 90 mm a 225 mm (diametro o lunghezza laterale) e valutazioni di potenza di 3W, 6W, 9W, 12W, 15W, 18W o 24W.

La seconda categoria è di dimensioni non standard, tipicamente progettate in base a requisiti di progetto specifici e ai parametri dimensionali unici.

La terza categoria è di dimensioni standard, tra cui 300x300mm, 300x600mm, 600x600mm, 300x1200mm e 600x1200mm. Alcune regioni possono avere lievi variazioni nelle dimensioni. Ad esempio, le dimensioni di un 60×60 pannelli sono generalmente 595x595mm in Cina, 595x595mm nella maggior parte dell'Europa, 600x600mm nella maggior parte del Sud America, 603x603mm in Nord America e 620x620mm in Germania e Brasile, tra gli altri.

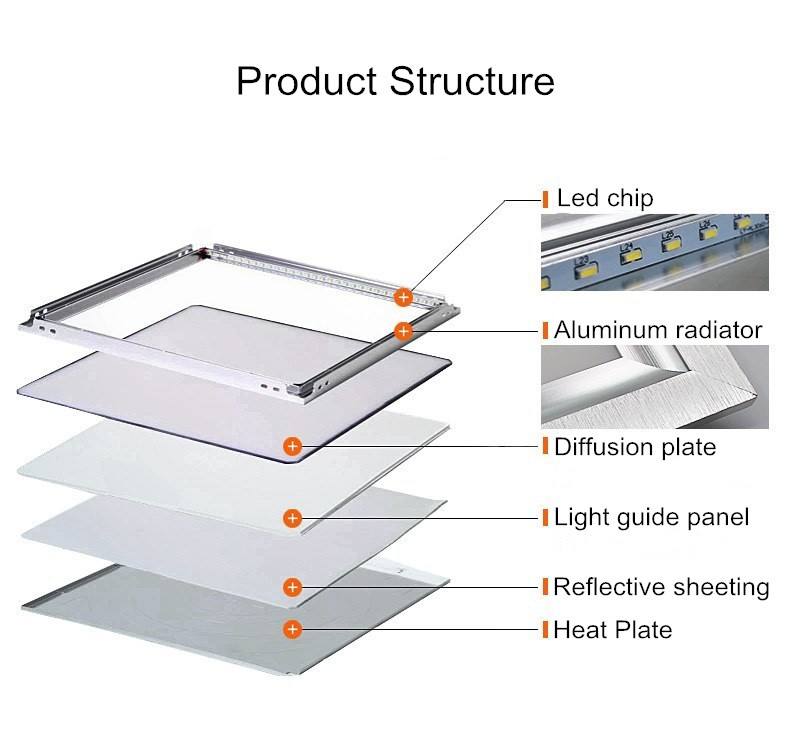

Struttura del prodotto

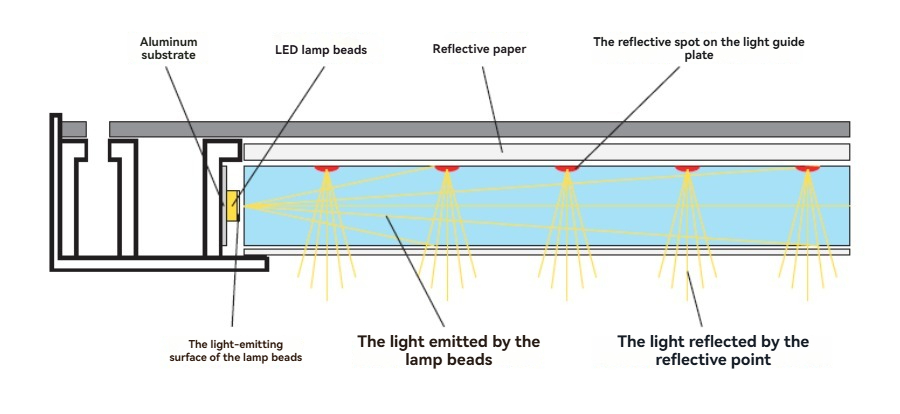

1)Struttura della luce del pannello illuminato a bordo LED e principio di emissione della luce:

La struttura di una luce del pannello a LED illuminata include principalmente componenti come la cornice, la piastra di diffusione, la piastra di guida alla luce, la striscia di luce, il film riflettente e il retro.

La luce dei chip a LED entra all'interno della piastra di guida della luce attraverso la superficie di emissione della luce. La luce viene riflessa dai punti riflettenti sulla piastra di guida della luce ed emessa verso il basso, quindi emessa attraverso la superficie di emissione della luce del apparecchio. La luce che non colpisce i punti riflettenti è riflessa dal film riflettente, garantendo che la maggior parte della luce dei chip a LED sia convertita in illuminazione utilizzabile. La qualità della piastra guida alla luce è un criterio importante per valutare la qualità complessiva del Bordo-illuminato Luce del pannello.

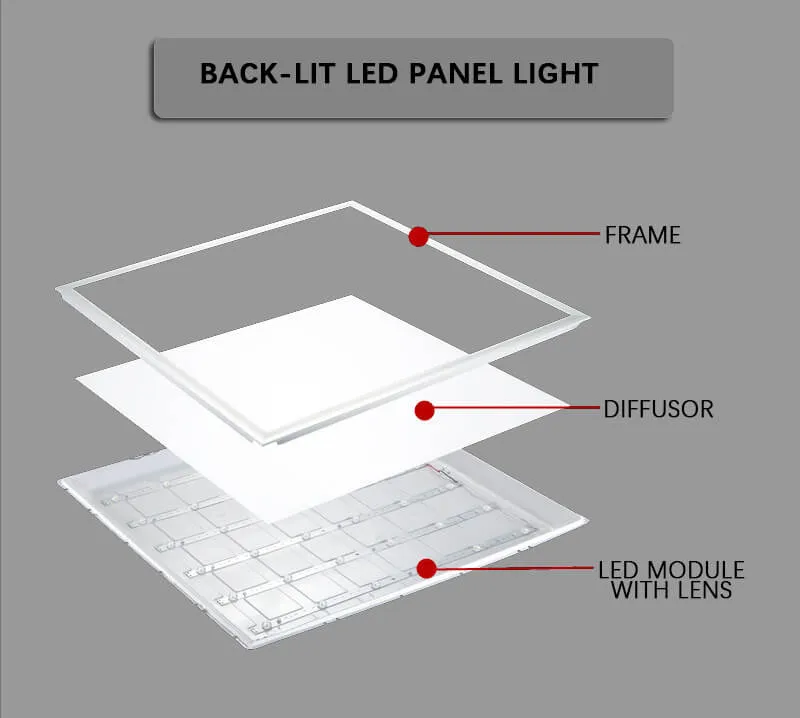

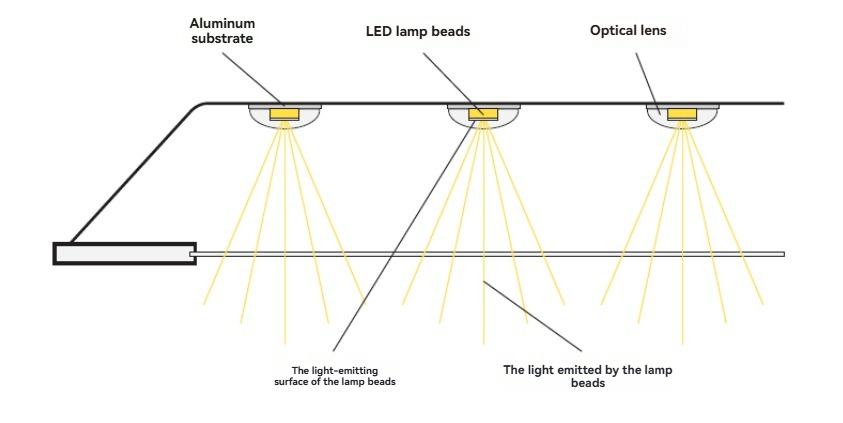

2) Struttura e principio di emissione della luce delle luci del pannello a LIT diretta a LED:

La struttura delle luci del pannello a illuminazione diretta (a emissione diretta) include principalmente un telaio, una piastra di diffusione, una striscia di luce (compresi il substrato di alluminio, i chip a LED e le lenti) e il coperchio posteriore.

La luce dei chip a LED è sparsa dalla lente e riflessa dalla copertina posteriore, emettendo dalla superficie di emettizzazione della luce del dispositivo.

Analisi dei componenti delle luci del pannello LED convenzionali

1.Frame: la resistenza del telaio influisce sulla durata e sulla qualità generale della lampada.

Il telaio è una parte importante della luce del pannello. Una cornice ad alta resistenza rende il pannello leggero più resistente. I materiali utilizzati per i frame laterali delle luci del pannello a LED variano, con conseguenti diverse prestazioni di dissipazione del calore. I materiali attuali per i telai delle luci del pannello includono principalmente lega di alluminio, acciaio, PC, A6063, composito in plastica in alluminio e acciaio. Il più comunemente usato è il telaio in alluminio (per le luci dei pannelli piccoli, alcuni usano alloggiamenti di plastica), che è ulteriormente diviso in cornici assemblate e saldate. I telai saldati sono più robusti ma più costosi delle cornici assemblate. Generalmente, le cornici sono classificate in base allo stile in cornici piane e frame a gradini, con differenze di prezzo. Inoltre, il peso del telaio (quantità di materiale utilizzato) influisce anche sul prezzo.

2.Patatine a LED

Il tipo, il marchio e la quantità di chip a LED influenzano l'effetto di illuminazione, il flusso luminoso e il prezzo. I chip a LED comunemente usati includono SMD2835 e SMD4014, con marchi come Sanan, Sumsang e Lumileds (precedentemente Philips). I chip a LED dei produttori di marca sono più costosi. Le luci del pannello a illuminazione diretta, a causa della luce dei LED che vengono sparse attraverso lenti ottiche, richiedono generalmente un numero significativamente inferiore di LED rispetto alle luci del pannello illuminate.

3.Plate di diffusore: Materiali diversi hanno trasmissione di luce diversa

La piastra di diffusore serve a distribuire uniformemente la luce dalla piastra di guida della luce e aiuta anche a sfocare la pixelzione. I materiali comuni includono PC, acrilico, PS e pp. I prezzi vanno da alto a basso, con PS e PC i più comunemente usati.

L'acrilico ha una trasmittanza leggera del 92%, il PC è dell'88%e PS è di circa l'80%. L'acrilico ha una maggiore trasmittanza della luce rispetto al PC e costi inferiori, ma ha una resistenza di invecchiamento più debole; Il PC è più costoso ma ha una resistenza all'invecchiamento più forte. Inoltre, diversi produttori usano spessori diversi per piastre di diffusione, con il più comune di spessore da 0,8 mm a 1,2 mm, che sono più costosi. Le luci del pannello a emissione diretta richiedono una maggiore resistenza nella piastra di diffusione rispetto a Bordo-illuminato luci del pannello e sono generalmente più spessi.

4.Piastra guida luminosa (LGP)

La piastra di guida della luce è un componente delle luci del pannello illuminate. Il materiale è un fattore significativo che influenza l'efficienza della luce oltre ai chip a LED. La sua funzione è di rifrattare la luce parallela alla direzione della piastra di trasmissione della luce in luce perpendicolare alla direzione della piastra di trasmissione della luce. La luce rifratta dalla piastra di guida della luce viene quindi riflessa dalla carta riflettente sul retro della luce del pannello. Durante questo processo, è anche importante ridurre al minimo il decadimento della luce. Generalmente, l'efficienza della luce della piastra di guida della luce dipende in gran parte dal design del motivo a punti, seguita dalla scelta del materiale (trasmittanza). I materiali comunemente usati includono PMMA (acrilico), MS e PS, con prezzi che diminuiscono in quell'ordine. Tuttavia, PS e MS tendono a gialli nel tempo, con PS in giallo tipicamente dopo circa due anni e MS dopo circa tre anni. Nelle regioni con temperature più elevate, le piastre di guida della luce sono più inclini al giallo. Se è necessaria una garanzia di 5 anni o una maggiore efficienza della luce, vengono generalmente utilizzate guide di luce PMMA. Le dimensioni delle guide di luce utilizzate da vari produttori generalmente vanno da 1,6 a 3,0 mm, con opzioni più spesse più costose.

5.Foglio riflettente

I fogli riflettenti vengono utilizzati nelle luci del pannello per riflettere la luce sparsa nel sistema di guida alla luce, migliorare l'efficienza della luce, migliorare l'uniformità della luminosità e prevenire la perdita di retroilluminazione.

6.Backplate

Il backplate più comunemente usato è realizzato in ferro, con diversi spessori e pesi con conseguenti punti di forza. Rispetto a Bordo-illuminato Le luci del pannello, le luci del pannello illuminate hanno un design diverso, con piastre più spesse. Inoltre, le piastre dei backplate delle luci del pannello a illuminazione diretta subiscono un rivestimento in polvere, che non solo fornisce colore ma migliora anche la riflettività.

7.Alimentazione del conducente

I prezzi variano in base al marchio, alla tensione, all'isolamento (isolato è più sicuro), senza sfarfallio (influenza se la luce appare senza sfarfallio se fotografata con un telefono), requisiti funzionali (ad es. Dimming e regolazione del colore) e requisiti di certificazione.

8.Anti-Glare Film

Requisiti antiriflesso (Ugr < 19 Per prevenire la tensione oculare) richiedere l'installazione di un film antiriflesso davanti al pannello del diffusore o usando un pannello di diffusore con effetti UGR integrati.

9.Accessori di installazione

Le clip a molla e le staffe di montaggio sono generalmente selezionate in base alle diverse esigenze dei clienti.

Vantaggi e svantaggi dell'illuminazione del pannello LED illuminato e ribasso

Bordo-illuminato Le luci del pannello offrono vantaggi come semplicità estetica, eleganza e lusso, illuminazione uniforme e morbida, spessore ultra-sottile e facilità di installazione e trasporto; Tuttavia, sono difficili da raggiungere un'elevata efficacia luminosa, attualmente circa 120 lm/w, che richiede costi significativi. Inoltre, le luci del pannello che utilizzano le guide di luce PS e MS possono gialli nel tempo.

Le luci del pannello illuminato posteriore hanno il vantaggio di processi di tecnologia e produzione più semplici, con linee di produzione semi-automatizzate che riducono i costi di manodopera. Offrono una luminosità sufficiente e possono ottenere un'elevata efficacia luminosa, raggiungendo attualmente 135 lm/w, con un ingiallimento minimo dell'apparecchio e un vantaggio di prezzo rispetto ai modelli illuminati da bordi; Gli svantaggi includono un design più spesso e più voluminoso, che appare meno premium rispetto alle luci del pannello illuminate e all'aumento del volume dell'imballaggio e dei costi di spedizione. A causa della loro struttura vuota, hanno requisiti di trasporto più elevati rispetto alle luci del pannello illuminate. Alcune luci del pannello a illuminazione diretta possono avere zone scure lungo i bordi del telaio, in particolare nei modelli con coperture posteriori inclinate. Attualmente sono emersi progetti di bordo destro per le luci del pannello a illuminazione diretta, eliminando le zone scure e migliorando l'uniformità della luce.

Come produttore professionista, siamo specializzati nella produzione di piastre guida alla luce di alta qualità (LGP), piastre di diffusore e film riflettenti. Con anni di esperienza nei componenti del pannello a LED, forniamo soluzioni affidabili, efficienti e personalizzabili per soddisfare vari requisiti di illuminazione. Collabora con noi per materiali superiori e supporto di esperti nel tuo prossimo progetto di pannello LED.

Soluzioni di retroilluminazione personalizzate & Fornitore di fogli ottici – Rnoda Tech

Soluzioni di retroilluminazione personalizzate & Fornitore di fogli ottici – Rnoda Tech