1.導光板とは何ですか?

導光板は光学グレードのアクリルシートを使用し、反射率が高く光を吸収しないハイテク素材でコーティングされています。 UV スクリーン印刷技術を使用して、導光ドットが光学グレードのアクリル シートの下側に印刷されます。

2.アクリル導光板の材質は何ですか:

アクリル導光板の主な素材は光学グレードのアクリル板です。現在、アクリル導光板はメーカーごとに製造工程が異なり、品質にばらつきがあります。特に、生シートは安価ではありますが、黄変しやすく、光透過率も悪くなります。アクリル導光板を製造する場合、黄変しにくく、光線透過率が92%~93%以上の透明シートを使用することが必須です。

現在、市販されている導光板にはアクリル板とPCシートの2種類の素材が使われています。ただし、アクリル シート ベースのライト ガイドの方が一般的ですが、PC シート ベースのライト ガイドはそれほど一般的ではなく、通常はカスタム製造が必要であり、すべてのライト ガイド メーカーがそれらを製造しているわけではありません。

3.アクリル導光板の仕組みは?

導光板には光学グレードのアクリル板を使用しています。次に、高い反射率と低い光吸収を備えたハイテク材料を使用して、UV スクリーン印刷技術を使用して光学グレードのアクリル シートの底面にライト ガイド ポイントを印刷します。

光学グレードのアクリルシートはランプから発せられる光を吸収し、表面に保持します。導光点に光が当たると、反射光はさまざまな方向に広がり、反射条件を破ってアクリル導光板の前面から出射します。

アクリル導光板は、密度や大きさを変えた導光点を使用することで均一な光を発することができます。反射シートを使用することで、底面から発せられた光をアクリル製導光板内に反射し、光の利用効率を高めます。

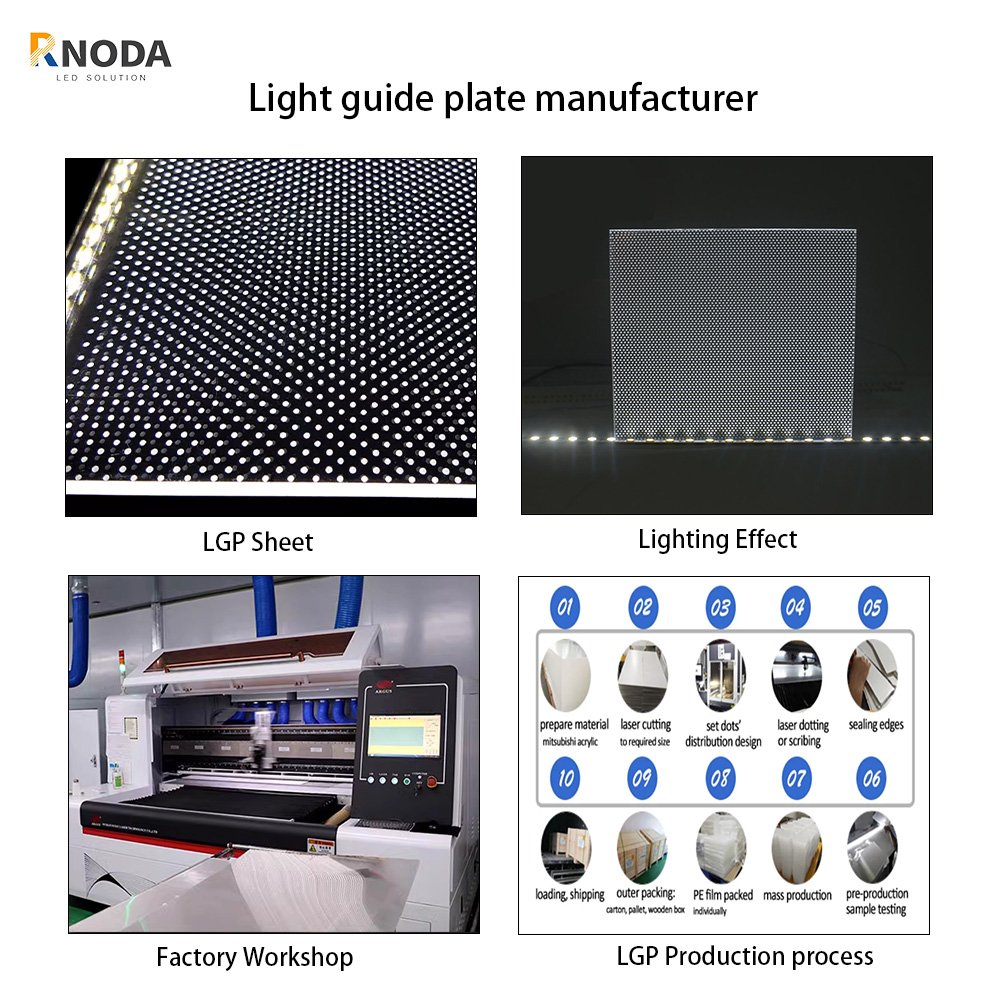

アクリル導光板の製造方法は主に2つあります。

スクリーン印刷と非印刷。スクリーン印刷された導光パネルは、投資が最小限で設備も不要で、手動で操作できるため、低コスト、高い生産効率、および単純な技術プロセスが得られます。

カスタマイズされたバックライトソリューション & 光学シートサプライヤー – Rnoda Tech

カスタマイズされたバックライトソリューション & 光学シートサプライヤー – Rnoda Tech