O que é folha LGP?

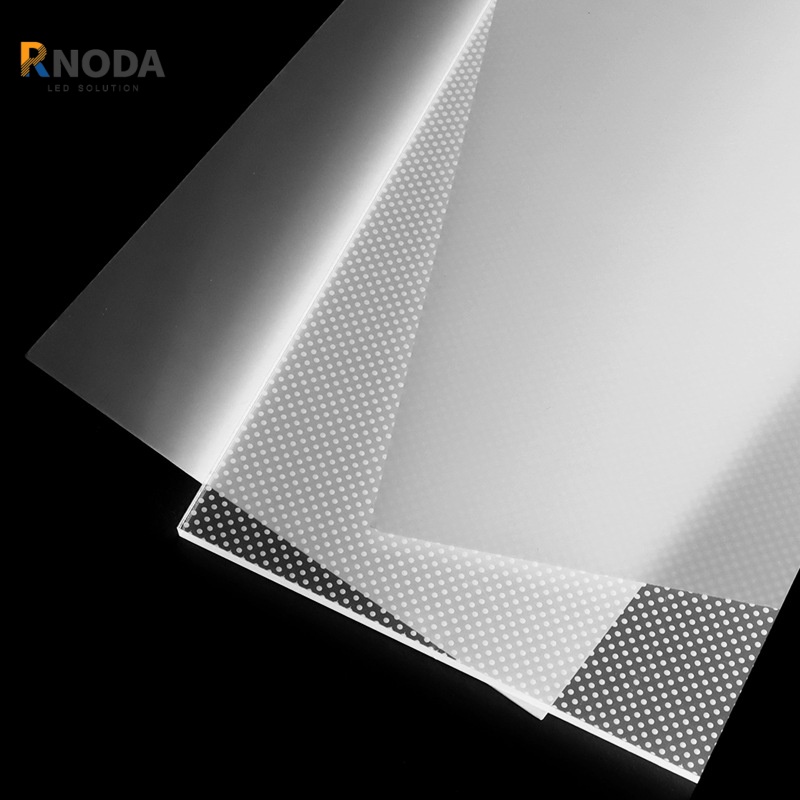

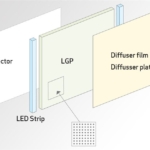

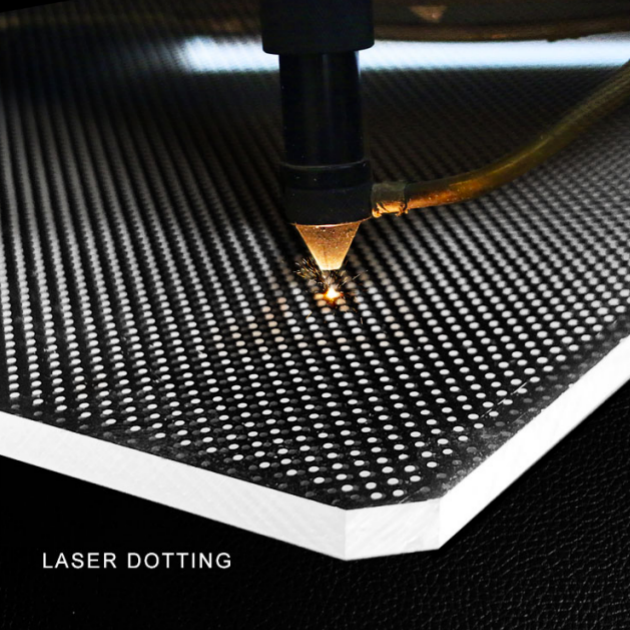

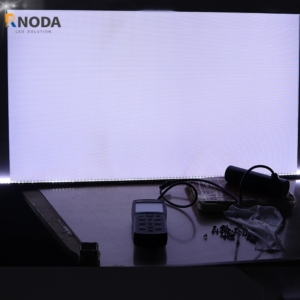

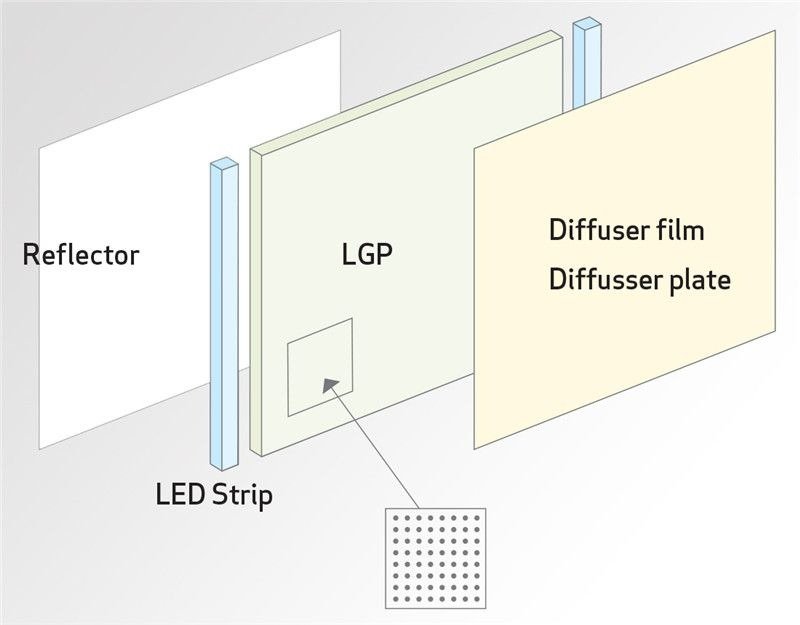

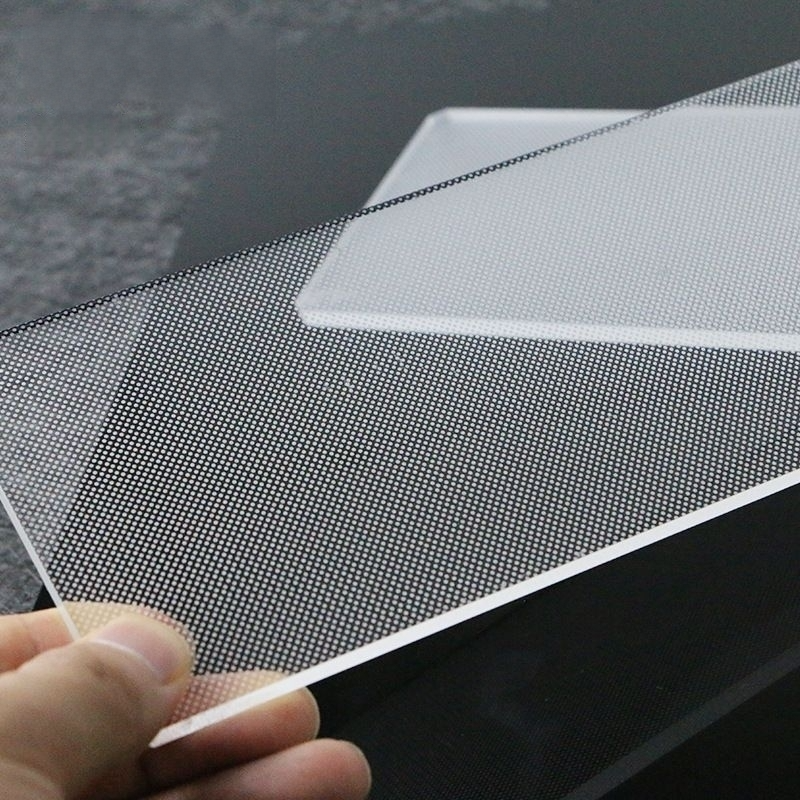

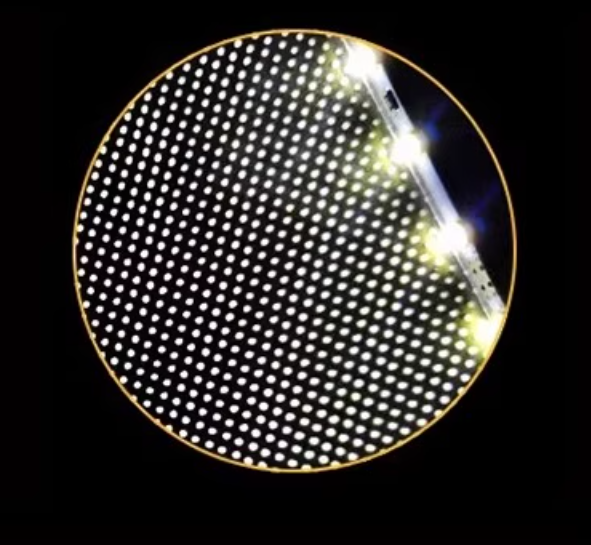

Folha LGP (Placa de guia leve) é um material da folha óptica usado para guiar e distribuir uniformemente a luz, amplamente aplicada nos módulos de luz de fundo, luzes do painel de LED, caixas de luz de publicidade e vários dispositivos de exibição e iluminação. A placa de guia de luz emprega processos especiais (como padronização de pontos a laser ou serigrafia de tela) para criar estruturas ópticas microscópicas na superfície do material, convertendo fontes de luz de ponto em fontes de luz difusas uniformes, alcançando assim a distribuição eficiente e uniforme da luz e um efeito visual suave.

Light Guide Plates vários materiais:

PMMA (acrílico): Alta transmitância de luz, excelente resistência ao clima e propriedades mecânicas, adequadas para dispositivos de iluminação e exibição de ponta.

Ps (poliestireno): Baixo custo, boa transparência, adequado para aplicações gerais de iluminação e luz de fundo.

MS (metacrilato de metila): Excelente transparência e desempenho óptico, uma das alternativas ao acrílico.

PC (policarbonato): Alta resistência e resistência ao impacto, adequadas para aplicações que requerem durabilidade.

Diferentes materiais de guias de luz podem ser selecionados com flexibilidade com base em ambientes de uso específicos e requisitos de desempenho, equilibrando a transmissão de luz, uniformidade, resistência ao calor e custo-efetividade.

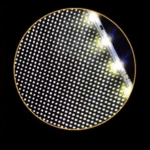

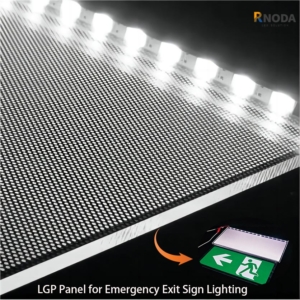

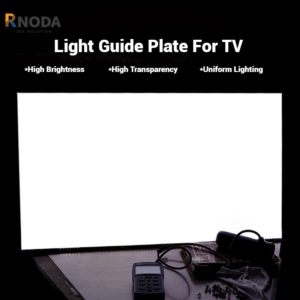

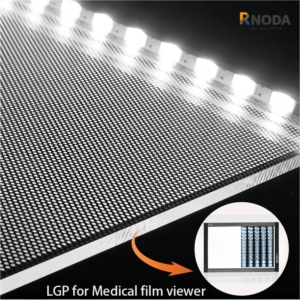

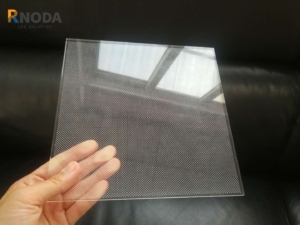

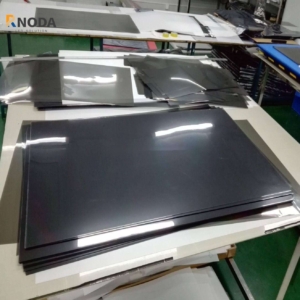

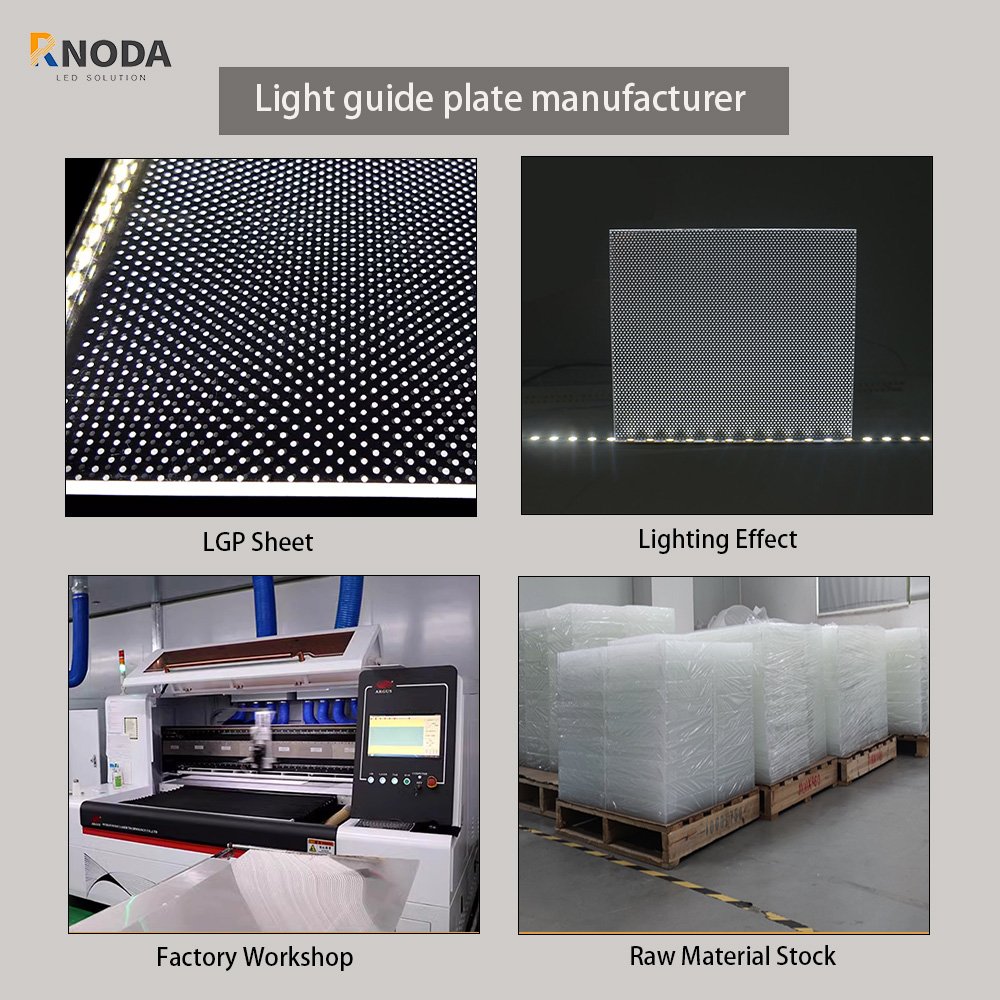

Imagens do produto:

Especificações do produto

| Nome do produto | Folha de LGP para painéis de iluminação comercial LED |

| Grossura | 3mm, 4 mm, 6mm, 8 mm, 10 mm |

| Cores | Alto transparente |

| Densidade | 1,2 g / cm3 |

| Aplicativo | Uma nota, pode ser usada para publicidade, iluminação, iluminação de fundo etc |

| Material | PMMA, PS, PC, MS |

| MOQ | 100 peças |

| Embalagem | Filme PE ou papel kraft de ambos os lados, palete de madeira |

| Prazo de entrega | 7-15 dias (de acordo com suas necessidades e tamanho personalizado) |

Principais vantagens da folha LGP

1) O acrílico óptico de alta transmissão de luz garante a transmissão uniforme da luz.

2) A tecnologia avançada da placa de guia de luz melhora a eficiência luminosa e reduz o consumo de energia.

3) Múltiplas espessuras e tamanhos podem ser personalizados para atender às diversas necessidades de design.

4) O processamento da superfície do ponto a laser alcança orientação uniforme da luz e manchas de luz suave.

5) Boa estabilidade e resistência climática, adequadas para uma variedade de ambientes.

Perguntas frequentes

Q1: Qual é a diferença entre a folha LGP e a folha de acrílico comum?

A1: A folha de LGP passa por processamento especial da matriz de pontos a laser para otimizar a orientação e a uniformidade da luz, tornando -os adequados para iluminação de fundo, enquanto o painel de acrílico comum não sofre esse processo.

Q2: Você é o fabricante da folha LGP?

Sim, somos bem -vindos para verificar mais detalhes.

Q3: As dimensões e a espessura podem ser personalizadas de acordo com os desenhos?

A3: Sim, apoiamos a personalização de dimensões, espessura e processo pontilhado de laser de acordo com os requisitos do cliente.

Q4.Você também pode fornecer folhas de difusor e filmes refletors?

A4: Sim, oferecemos uma solução completa, incluindo folhas LGP, folhas de difusores e filmes refletors. Esses componentes podem ser fornecidos como um conjunto correspondente para garantir o desempenho ideal da luz de fundo.

Q5: Você oferece testes de amostra?

A5: Sim, entre em contato conosco para solicitar uma amostra.

Q6: Como podemos garantir a qualidade?

A6: Amostras de pré-produção e inspeções finais são sempre garantidas para a garantia de qualidade.

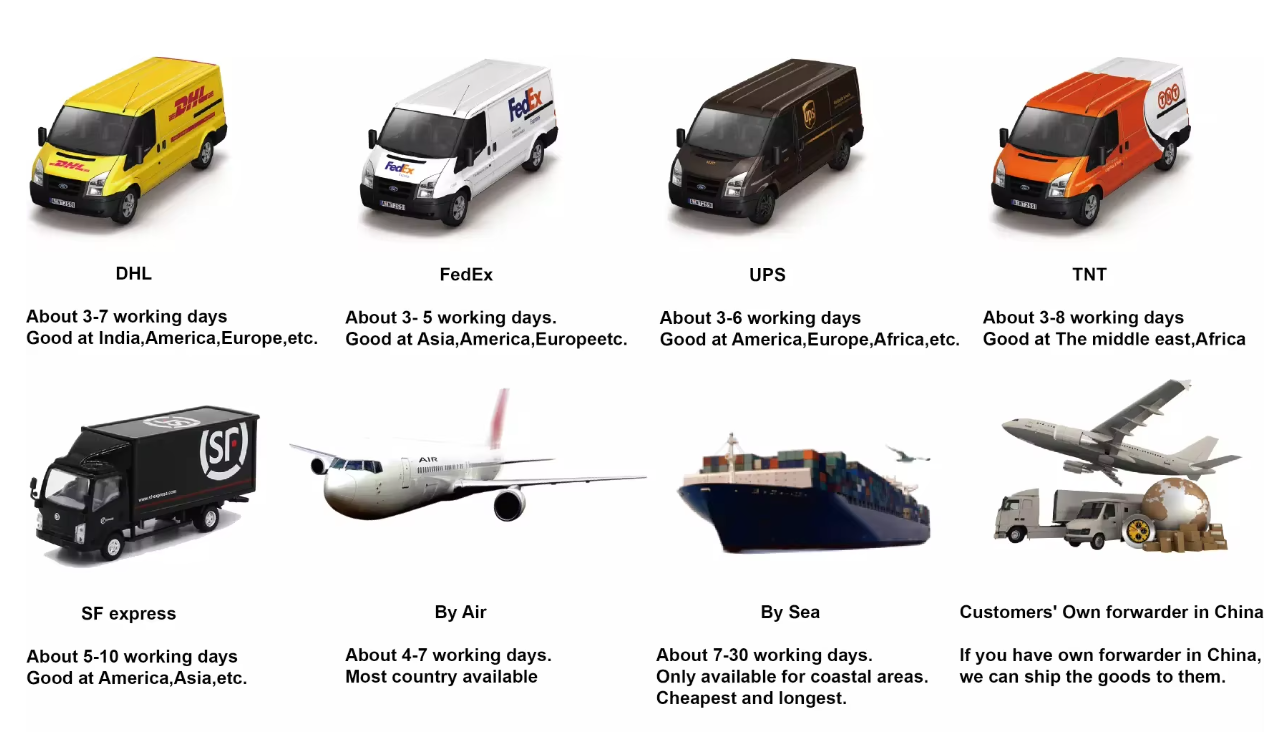

Q7: Quais métodos de envio você oferece e quanto tempo dura o tempo de entrega?

Q7: As mercadorias geralmente são entregues por meio de serviços expressos confiáveis como DHL, UPS, FedEx ou TNT, que levam aproximadamente 3 a 5 dias. Também apoiamos as opções de frete aéreo e marinho com base no volume e no destino do seu pedido.

Soluções de luz de fundo personalizadas & Fornecedor de folhas ópticas – Rnoda Tech

Soluções de luz de fundo personalizadas & Fornecedor de folhas ópticas – Rnoda Tech