What Is a Diffuser Film in LCD Backlight Modules?

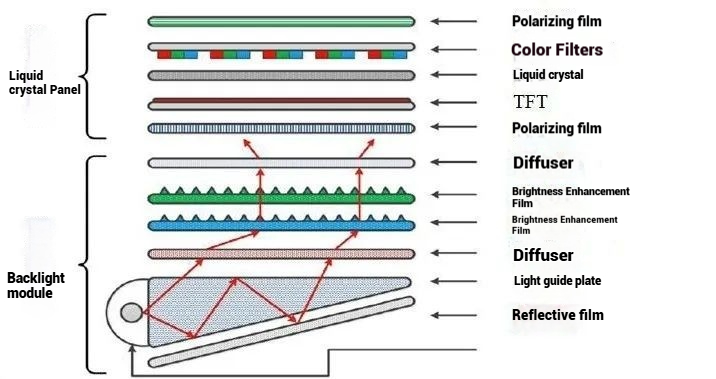

As a typical passive light-emitting device, TFT-LCD liquid crystal display panels require an external light source to achieve display imaging. Therefore, a backlight module must be added to the rear of the TFT-LCD.

A complete TFT-LCD liquid crystal display module utilizes numerous LCD optical films, such as polarizer sheet, Assim, filmes de difusão, Assim, brightness enhancement films(BEF), and reflective films.

Except for the polarizer sheet, which are bonded to the top and bottom surfaces of the TFT-LCD panel, the other LCD optical sheets are fixed in various ways to the backlight’s metal or adhesive frame. Together with other components, they form a complete backlight module.

This article focuses on the classification and functions of diffuser films.

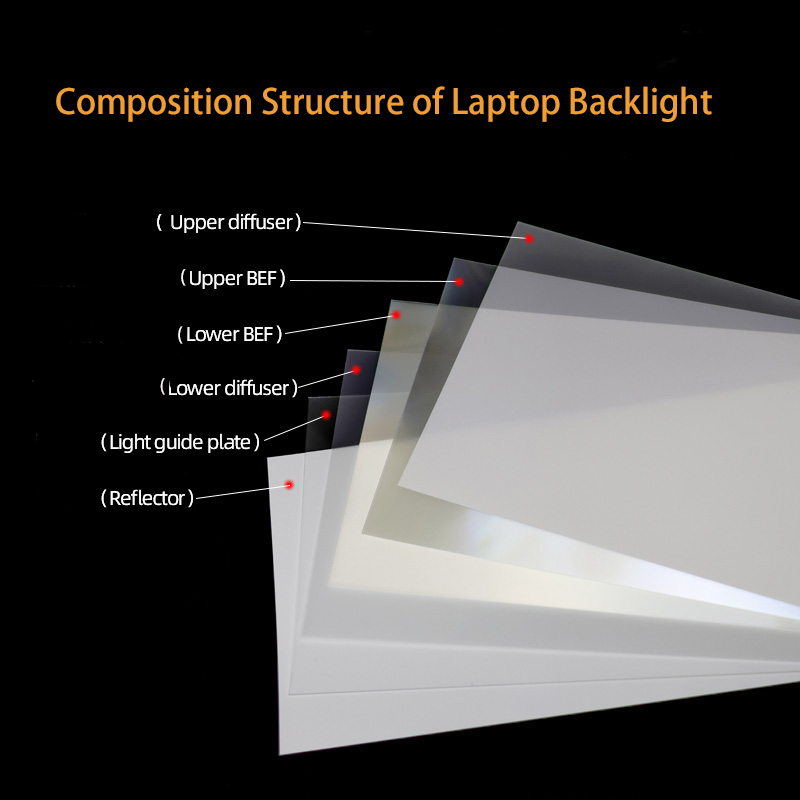

Diffuser films are generally categorized into two types: upper diffusion film and lower diffusion film. Their functions and application scenarios differ significantly.

Compared to the upper diffusion film, the lower diffuser film appears whiter, has higher haze, and lower light transmittance; while the upper diffuser film is more transparent, features higher light transmittance, and lower haze.

I. Upper Diffusion Film Key Features and Applications

Upper Diffusion Film: Positioned above the upper and lower light-enhancing films within the backlight module, its primary functions include:

① Protecting light-enhancing films and improving assembly yield. Situated above the light-enhancing films in the backlight module structure, it shields them from external scratches and reduces contamination from environmental particles and dust.

② Improves viewing angles. The upper diffusion film increases light emission angles, ensuring optimal visual effects when viewing the LCD panel from different angles.

③ Enhances light softness. The upper diffusion film softens light intensity and sharpness, creating a more comfortable viewing experience and reducing eye strain.

Upper diffusion films are primarily used in mid-to-high-end laptops, automotive displays, industrial controls, MNTs, and TVs. They are rarely employed in small-to-medium-sized products like wearables, smartphones, and tablets.

II. Lower Diffusion Film Functions and Usage in LCD Panels

Lower Diffusion Film: Positioned above the light guide plate within the backlight module, its primary functions are:

① Ensuring uniform light distribution. Situated above the light guide plate, the lower diffusion film refracts and scatters light as it passes through its diffusion layer. This transforms the light into a uniform surface light source, enhancing the backlight module’s light uniformity.

② Improving blemish concealment. The light guide plate(LGP) features dot patterns that refract light. The lower diffusion film partially obscures these dots, preventing visible dot patterns or defects caused by uneven dot distribution, minor scratches, or contamination when light passes through the plate.

The lower diffusion film is widely used and indispensable in TFT-LCD display modules. However, some TV products may substitute the lower diffusion film with a diffusion plate.

Soluções de luz de fundo personalizadas & Fornecedor de folhas ópticas – Rnoda Tech

Soluções de luz de fundo personalizadas & Fornecedor de folhas ópticas – Rnoda Tech