In modern optoelectronics and display technology, various optical films play a pivotal role in displays. From polarizer films to light guide plates, from diffusion films to Brightening Enhancement Films, they alter light propagation, enhance display quality, and improve energy efficiency. But how did these films originate? What insteresting stories lie behind them? Let’s explore their origins and evolution of optical films.

The Birth and Evolution of Polarizer sheets

A polarizer sheet is an optical film that allows light waves to vibrate along a specific direction. The most widely used polarizer—the H-plate—was invented by Land in 1938. Its manufacturing process involves immersing a transparent plastic sheet (typically PVA) in an iodine solution, followed by heating and stretching. This stretching process aligns PVA molecules along the direction of tension, causing iodine ions to form long-chain structures. This alignment grants the film its polarization capability: it absorbs light parallel to the iodine ion alignment while transmitting light perpendicular to it.

The polarizer film industry first took root in Japan. In 1999, Taiwan’s Lite-On began production, breaking Japan’s long-standing monopoly. Subsequently, South Korea’s LG Chem commenced mass production of TFT polarizers in 2000. Mainland China’s polarizer projects began in 1994, and after several years of R&D, Shengbo Company successfully developed qualified products by late 1998. Currently, polarizer production in Japan and South Korea is gradually slowing down, making the mainland market the new focal point for industry development.

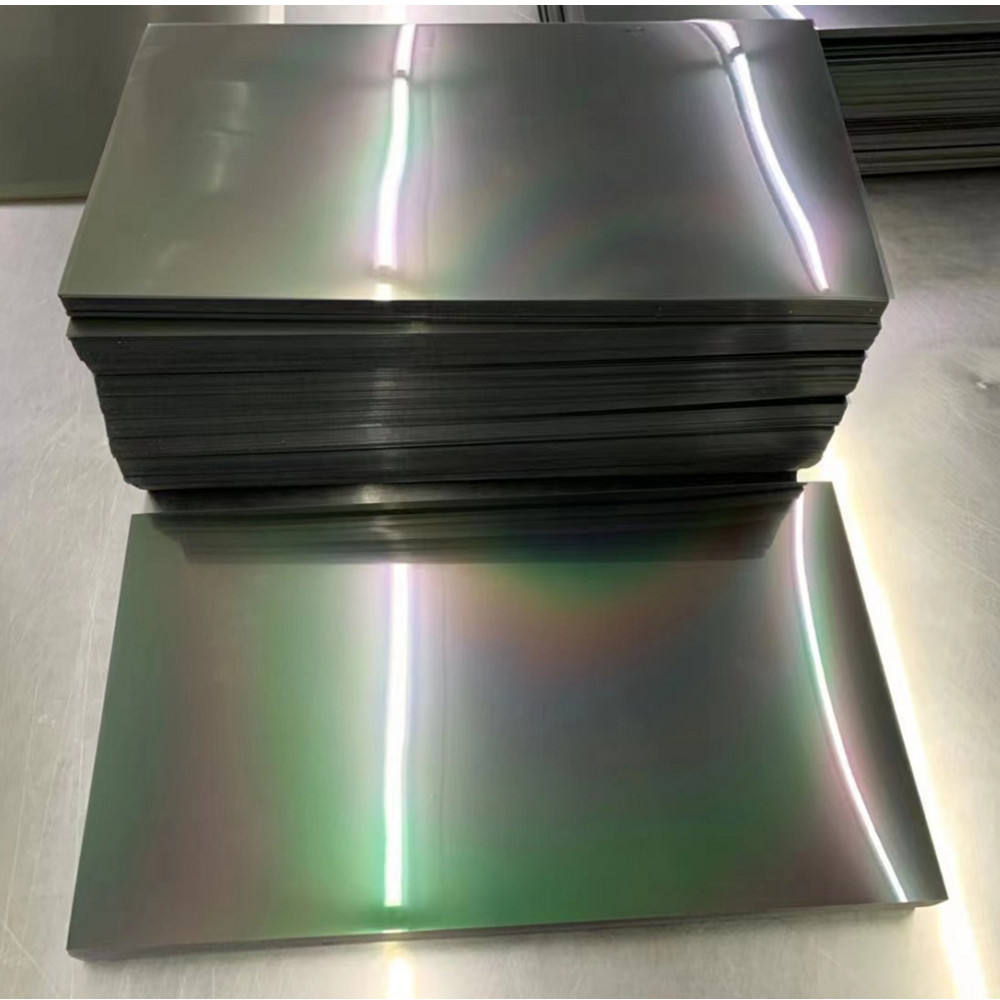

Placă de ghidare ușoară (LGP): Ensures uniform light distribution

Light guide plates are manufactured from optical-grade acrylic or PC sheets. UV screen printing of light-guiding dots on the substrate achieves uniform light distribution. Japan’s Meito Corporation invented EDGE LIGHT technology in 1986, introducing light sources from the plate edges. Utilizing total internal reflection principles, light is emitted from the plate surface to create uniform backlighting.

Due to their compact size, high brightness, and low energy consumption, light guide plates are widely used in notebook computers, digital cameras, LCD televisions, and other products, serving as core components of backlight systems.

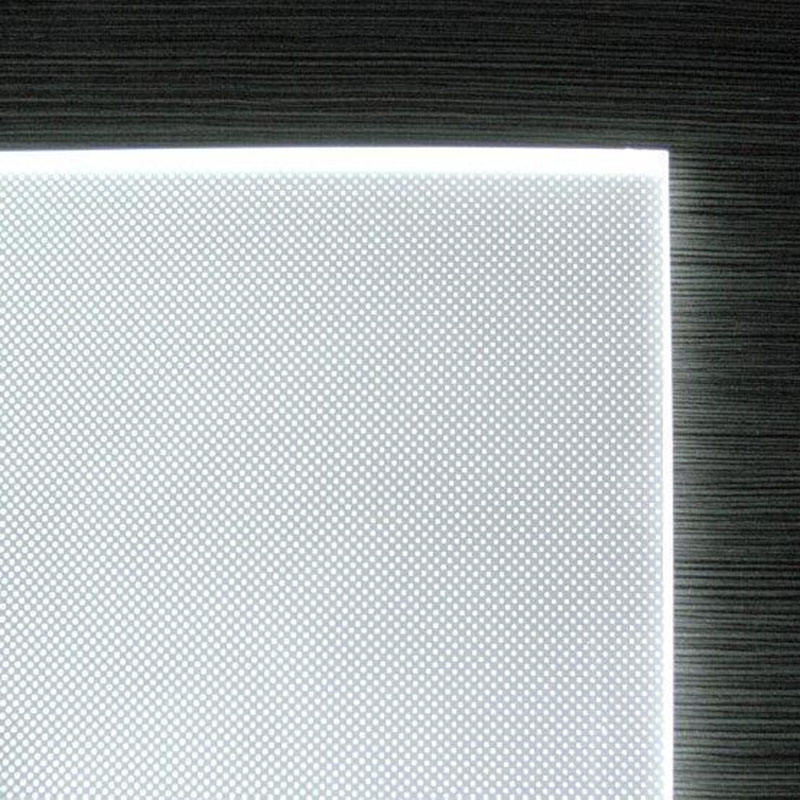

Diffusion Film: Softening and Evenly Distributing Light

Diffusion film uniformly scatters light to create a soft, glare-free illumination. Most diffusion films are manufactured by coating optical scattering particles onto transparent substrates like PET. Originating in Japan, Keiwa first introduced diffusion film products in 1990, followed by similar offerings from Tsujiden and Kimoto.

Diffusion films are widely used in LCD backlight modules, optical lighting equipment, and advertising displays, enhancing screen brightness uniformity and visual comfort.

Film reflectorizant: Maximizing Light Utilization

Reflective films enhance optical surface reflectivity through specialized coating processes. Common types include metal reflective films, all-dielectric reflective films, and metal-dielectric composite films. High-end multilayer reflective films comprise hundreds of nanometer-thick layers, achieving reflectivity of 99%–100%—significantly surpassing standard 95% reflectivity films.

Within recirculating brightness enhancement systems, reflective films substantially reduce light loss while boosting display brightness and energy efficiency, making them a critical component of modern LCD backlight technology.

Film de îmbunătățire a luminozității (BEF): 3M’s Ingenious Innovation

The origin story of Brightness Enhancement Film (BEF) is quite fascinating. Over two decades ago, 3M researchers in Quebec, Canada, discovered during basement experiments that prism-coated light pipes could transmit oblique sunlight along their walls, instantly illuminating the space. Subsequently, 3M scientists cut open these prism pipes and laid them flat over an LCD backlight, unexpectedly boosting the screen’s forward brightness.

Through micro-replication technology and multilayer optical film techniques, 3M further optimized the light-gathering efficiency of the prismatic tubes, ultimately launching the Brightness Enhancement Film (BEF). This product doubled the brightness of displays in laptops, LCD TVs, and other devices while reducing energy consumption, becoming an indispensable optical film for LCD displays.

Rezumat

From polarizer sheets to light guide panels, diffusion films, reflective films, and brightness enhancement films, each functional film originates from scientists’ creativity and experimentation. By altering light propagation, they enhance display brightness, uniformity, and energy efficiency, laying the foundation for modern display technology.

Today, these films are not only widely used in electronic products like smartphones, computers, and televisions, but also play significant roles in lighting, architecture, automotive, and energy sectors. The history of functional films is a story of the perfect integration of technological innovation and engineering practice.

Custom Optical Film Solutions

As a reliable optical film provider, we offer a wide range of customizable solutions to meet your specific requirements. Whether you need tailor-made sizes, special optical properties, or unique designs for your display or lighting applications, we can provide high-quality optical films to fit your needs. For any custom orders or inquiries, feel free to contactaţi-ne to discuss your project.

Soluții de fundal personalizate & Furnizor de foi optice – Rnoda Tech

Soluții de fundal personalizate & Furnizor de foi optice – Rnoda Tech