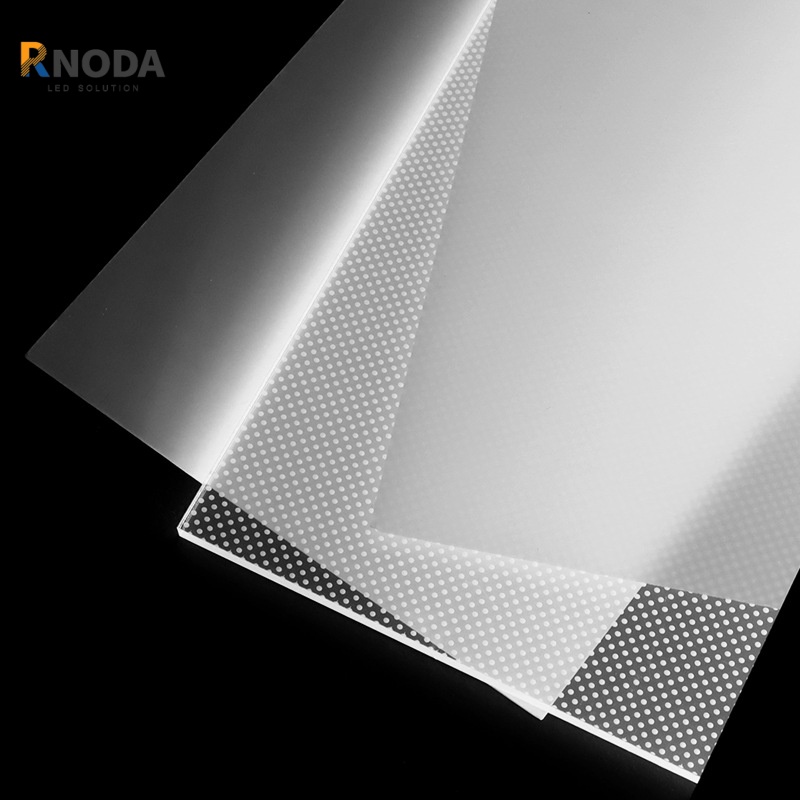

What is Acrylic (PMMA)?

Acrylic, also known as specially treated organic glass, is the next-generation product of organic glass.It is widely used as the base material for LED light guide panels due to its excellent optical properties.

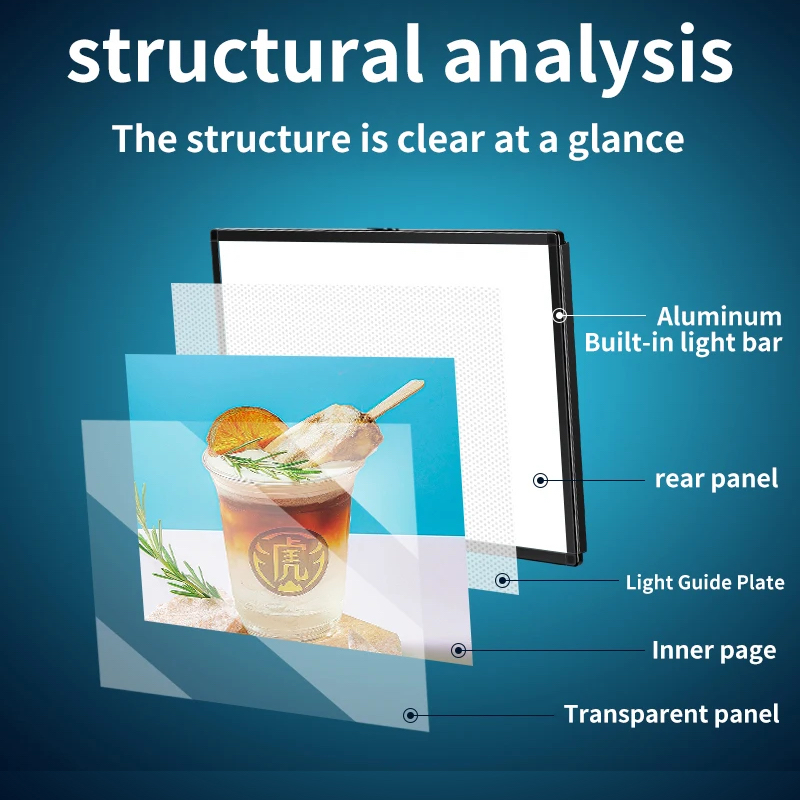

Advantages of Acrylic Light Boxes

Light boxes made from acrylic feature excellent light transmission, pure colors, rich hues, a smooth and aesthetically pleasing surface, dual daytime and nighttime effects, a long service life, and no impact on usability.

Why PMMA/Acrylic is Widely Used in LED Light Guides

Currently, PMMA/acrylic is widely used as the material for LED light guides in the market. Compared to organic glass, PC, and PS, it has advantages such as high light transmission, strong stability, and a wide temperature resistance range. The specific advantages, disadvantages, and precautions are as follows:

Compared to organic glass, acrylic has the following characteristics:

1. Excellent transparency. Colorless transparent acrylic sheets have a light transmission rate of over 92%. This high transparency is crucial for high-performance LED light guide panels.

2. Excellent weather resistance. It has strong adaptability to natural environments and does not undergo performance changes even after prolonged exposure to sunlight, wind, and rain, demonstrating excellent aging resistance.

3. Good processability. It is suitable for both mechanical processing and thermal formin. Making it versatile for different LED light guide designs.

4. Superior comprehensive performance. Acrylic sheets come in a wide variety of types and colors and possess excellent comprehensive performance.

Important Usage Precautions:

1. Acrylic sheets must not be stored with other organic solvents and must not come into contact with organic solvents.

2. During transportation, the surface protective film or protective paper must not be damaged.

3. They must not be used in environments where temperatures exceed 85°C.

4. When cleaning acrylic sheets, use only a 1% soap solution. Apply the solution with a soft cotton cloth; do not use hard objects or dry wipe, as this may easily scratch the surface.

5. Acrylic sheets have a large thermal expansion coefficient. When exposed to temperature changes, allow for expansion gaps.

โซลูชันแบ็คไลท์ที่กำหนดเอง & ซัพพลายเออร์แผ่นแสง – เทคโนโลยี rnoda

โซลูชันแบ็คไลท์ที่กำหนดเอง & ซัพพลายเออร์แผ่นแสง – เทคโนโลยี rnoda