For A+ grade products, the face film is generally selected from original factory full-sheet polarize filmi; for some products, TFT non-rotating triangular material may be used. The base film is generally selected from original factory full-sheet polarizing film. For A-grade products, the front sheet generally uses original factory-grade full-sheet polarizer film, TFT non-optical triangular material, or TFT scrap material polarizing film with higher inventory levels; or TFT scrap material polarizing film from suppliers that will no longer be the primary procurement channel in the future. The back sheet uses original factory-grade full-sheet polarizing film or composite back sheet.

For Grade B products, the front sheet should preferably use TFT scrap polarizer filmwith lower inventory levels, scrap pieces, or TFT scrap polarizing film from suppliers that are no longer the primary procurement channel; the back sheet should use composite back sheets. When customers have special requirements, special polarizing film should be selected according to customer specifications.

Usage instructions:

Handle with care; do not use hard objects to scrape the surface. Do not fold when handling. Grade sheets and scrap sheets must undergo color sorting before production. When applying the polarizer film, ensure that any residual cleaning solution on the LCD surface has completely evaporated before applying the polarizing film. When slitting ultra-wide temperature polarizing film, ensure the adhesive side is facing down.

Storage and Handling

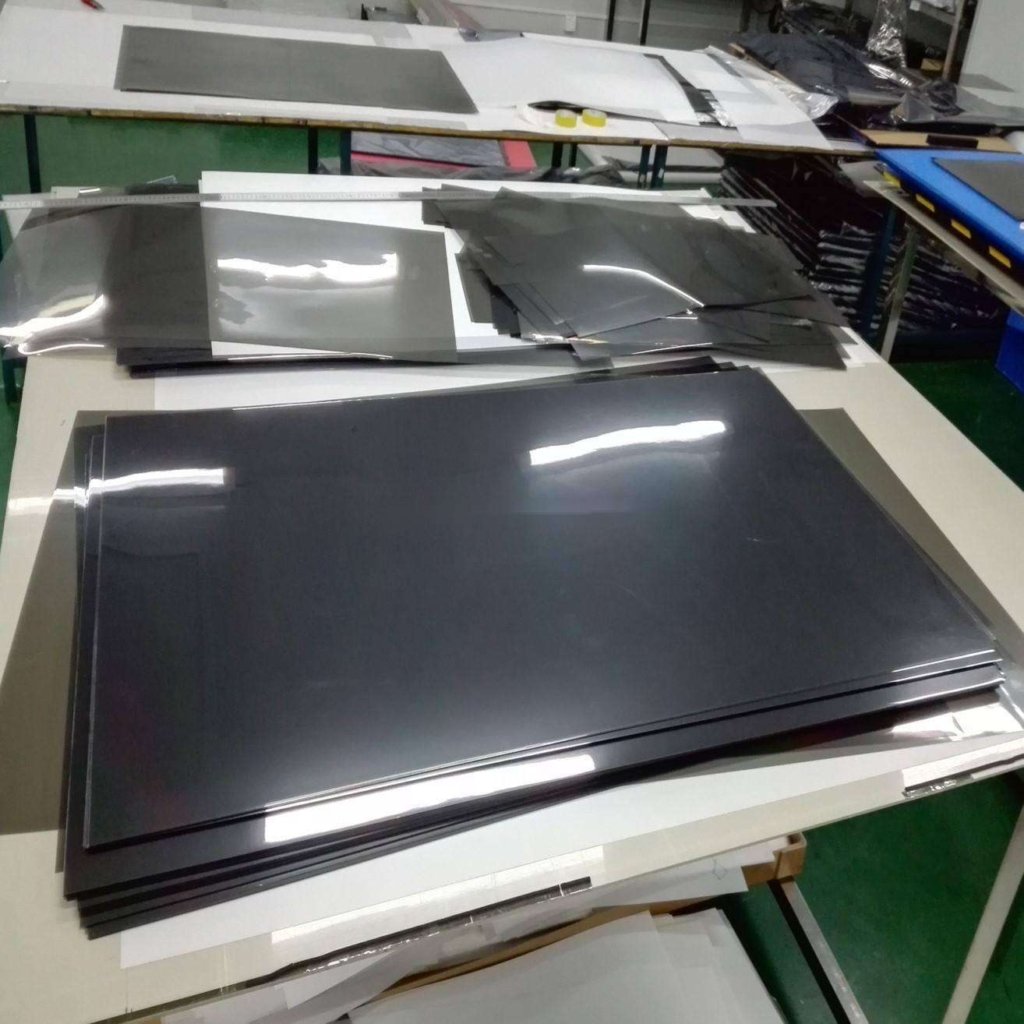

Storage of polarizing films: Polarizing films should be stored at room temperature, in a light-protected environment with humidity below 75%. They must be stored flat. Polarizing films in original supplier packaging should be stacked according to the supplier’s specified stacking height and position. For polarizing films in express packaging or bulk stacks, every 300 sheets must be stacked separately with support. Handling methods for polarizing films: When handling polarizing films, they should be placed on the upper layer of the handling material, with a height not exceeding the stacking height. They should be handled with care, not stacked vertically, and not subjected to impact or pressure.

Özelleştirilmiş Arka Işık Çözümleri & Optik sayfalar tedarikçi – Rnoda Tech

Özelleştirilmiş Arka Işık Çözümleri & Optik sayfalar tedarikçi – Rnoda Tech