Detailed explanation of the main causes of glass bending

1)Uneven adhesive tension / inconsistent coating thickness

LCD Polarizer film are generally adhered to LCD glass using PSA (Pressure-Sensitive Adhesive).

If the adhesive is applied unevenly (e.g., thick in some areas and thin in others), stress concentration will occur during the bonding process, causing the glass to bend slightly or even deform.

2)Lamination stress

LCD polarizer film lamination typically uses a laminating machine with rollers. During the process, excessive pressure, uneven speed, or misalignment can generate localized mechanical stress, particularly in large-sized glass or ultra-thin glass (e.g., 0.3mm, 0.5mm).

3)Mismatched Thermal Expansion Coefficients

The thermal expansion coefficients of polarizers, adhesive layers, and glass differ. During lamination or heating curing processes (e.g., using hot rollers), varying expansion rates among materials can cause overall glass deformation or bending.

This is particularly common in thermal lamination of polarizers (Thermal Laminating Polarizer).

4)Residual stress in the glass itself

If the glass already has residual stress from cutting or cleaning processes, external stress during polarizer lamination can release the original stress, causing bending.

This issue is more common in low-cost or recycled glass materials.

5) Curvature of the polarizer itself

Polarizers may develop a tendency to curve due to prolonged storage, moisture exposure, or heat exposure. When applied to glass, this curvature can exert a reverse force on the glass, causing deformation.

🛠 Solution Recommendations

- Use a constant-pressure control lamination device to maintain uniform pressure.

- Control the cleanliness, flatness, and alignment accuracy of the lcd polarizer and glass during lamination.

- Preheat/pre-treat the polarizing film for LCD and glass thoroughly before lamination to reduce stress differences.

- Use high-stability, low-shrinkage PSA adhesive.

- Inspect the flatness and residual stress of the glass, and perform heat treatment annealing if necessary.

How can we help you?

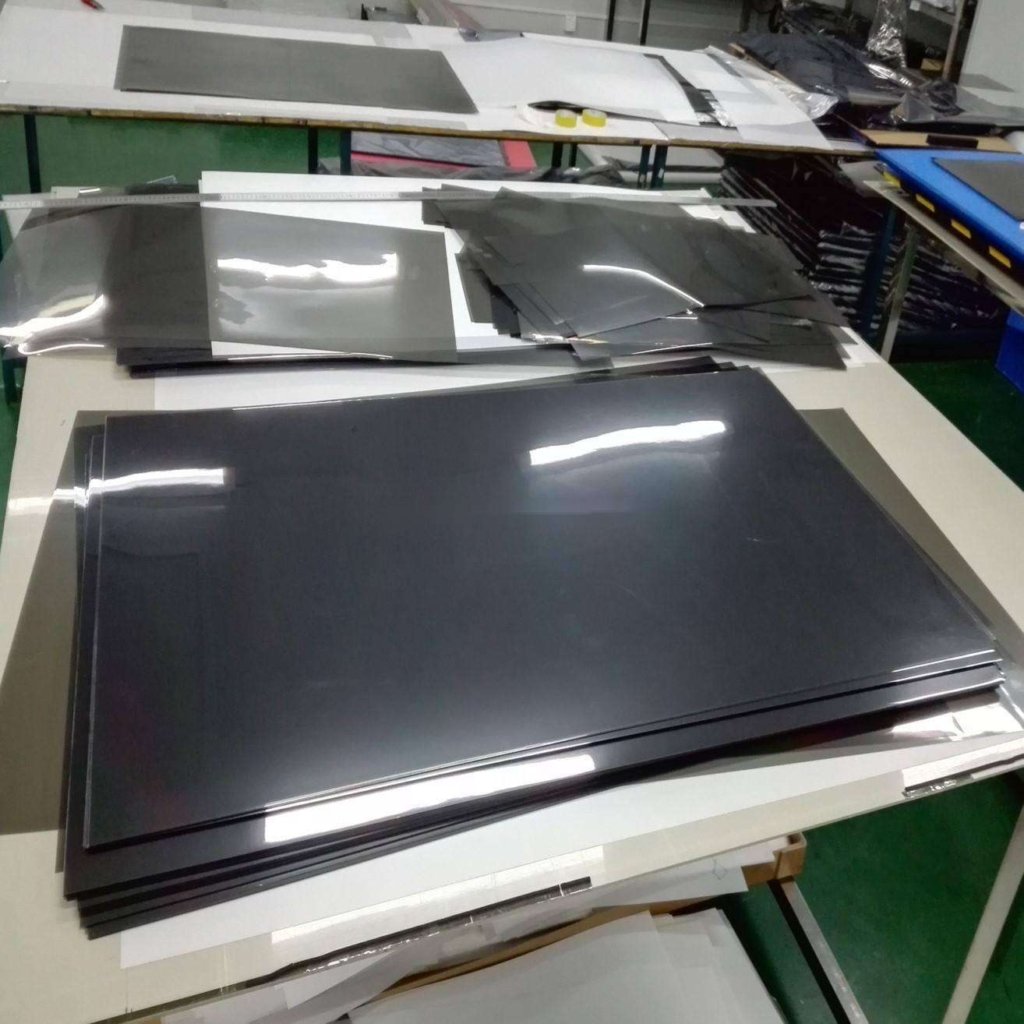

As a professional lcd polarizer film customization supplier, we offer:

- LCD Polarizer film in a variety of specifications (0°, 45°, 90°, and 135° available)

- Support for small-batch customization and batch orders

- Strict flatness control to minimize stress issues after lamination

- Support for various application scenarios including laptops, TVs, in-vehicle displays, and industrial displays

We understand the challenges you face in production, so we not only provide products but also offer personalized technical support and solution recommendations.

Özelleştirilmiş Arka Işık Çözümleri & Optik sayfalar tedarikçi – Rnoda Tech

Özelleştirilmiş Arka Işık Çözümleri & Optik sayfalar tedarikçi – Rnoda Tech