Nedir polarize filmi?

The full name of a polarizer film is a polarized light film. Those with a background in physics should be familiar with the concept of polarized light, which is essential for the imaging process in liquid crystal displays (LCDs). All liquid crystals are sandwiched between two polarizing films, which are tightly bonded to the liquid crystal glass, forming a liquid crystal panel with a total thickness of approximately 1 mm. If either of the polarizing films is missing, the liquid crystal panel will be unable to display an image.

Key Material in LCD Display Technology

Polarizer film are one of the key materials in LCDs. They are composite materials made by repeatedly laminating, stretching, and coating polyvinyl alcohol (PVA) stretch film and cellulose acetate film (TAC). These films enable LCDs to achieve high brightness and high contrast. polarizer film account for approximately 10% of the cost of TFT-LCD (thin-film transistor liquid crystal display) panels. Due to its production technology integrating high-polymer materials, microelectronics, optoelectronics, thin films, high-purity chemistry, and computer control, polarizing films have a high technical content. Currently, there are only a few domestic companies capable of producing polarizing films.

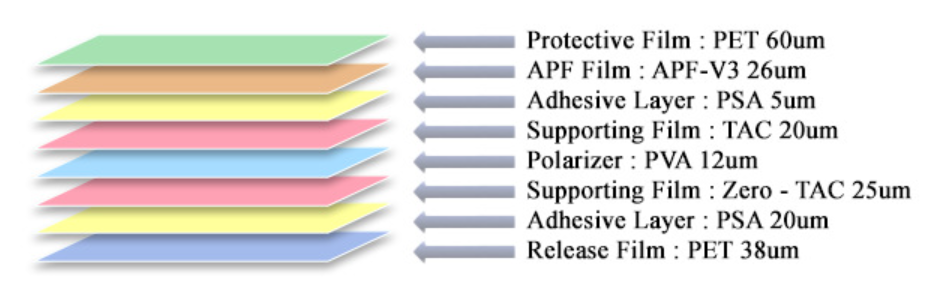

Structure of LCD polarizer film

The earliest polarizing films were primarily composed of a PVA film capable of generating polarized light in the middle, with TAC (transparent triacetate cellulose) protective films laminated on both sides. To facilitate use and achieve different optical effects, polarizing film suppliers, at the request of liquid crystal display manufacturers, coated both sides with pressure-sensitive adhesive and then applied a release film. This type of polarizing film is the most commonly seen TN ordinary fully transmissive polarizing film. If one layer of release film is removed and a reflective film is laminated, it becomes the most common reflective polarizing film.

Customization and Functional Types of Polarizer Films

The pressure-sensitive adhesive used is a high-temperature resistant and moisture-proof type, and the PVA undergoes special coating treatment (dye series products), resulting in a wide-temperature type polarizing film; by adding UV-blocking components to the pressure-sensitive adhesive, UV-blocking polarizing films can be produced; by laminating a birefringent optical compensation film onto the transmissive base film, STN-compatible polarizing films can be produced; By laminating a light-deflecting film onto the transmissive base film, wide-angle or narrow-angle polarizing films can be produced; by coloring the pressure-sensitive adhesive, PVA film, or TAC film, colored polarizing films can be produced. In fact, as new types of liquid crystal display products continue to be developed, the types of polarizing films are becoming increasingly diverse and are being used in an ever-wider range of applications.

Use of Polarizer Films in LCD Screen Refurbishment and Repair

In the liquid crystal industry, polarizing films are primarily used for replacing color liquid crystal screens, ranging from small smartphone screens to large 60-inch liquid crystal televisions. Screen scratches and aging of polarizing films can be restored to like-new condition through specific technical methods.

We can customize polarizer film sizes to meet your specific needs. For inquiries and orders, please feel free to contact us.

Özelleştirilmiş Arka Işık Çözümleri & Optik sayfalar tedarikçi – Rnoda Tech

Özelleştirilmiş Arka Işık Çözümleri & Optik sayfalar tedarikçi – Rnoda Tech