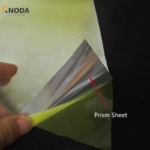

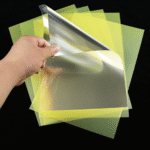

What is laptop prism film ?

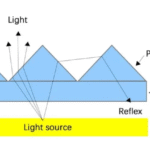

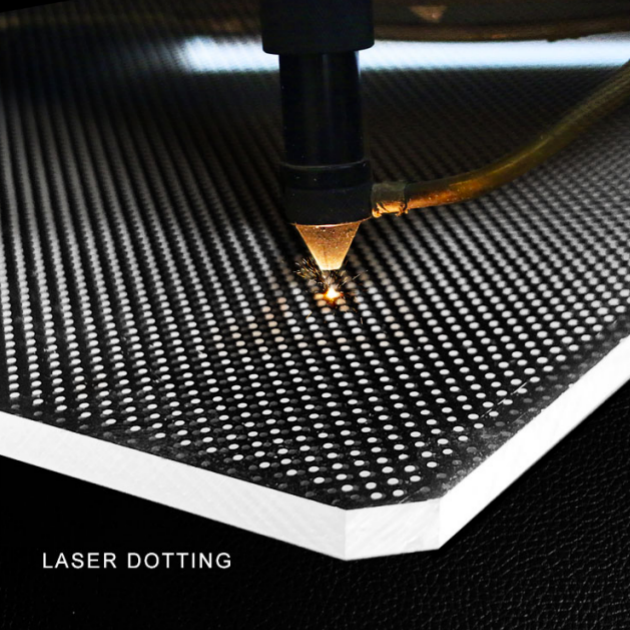

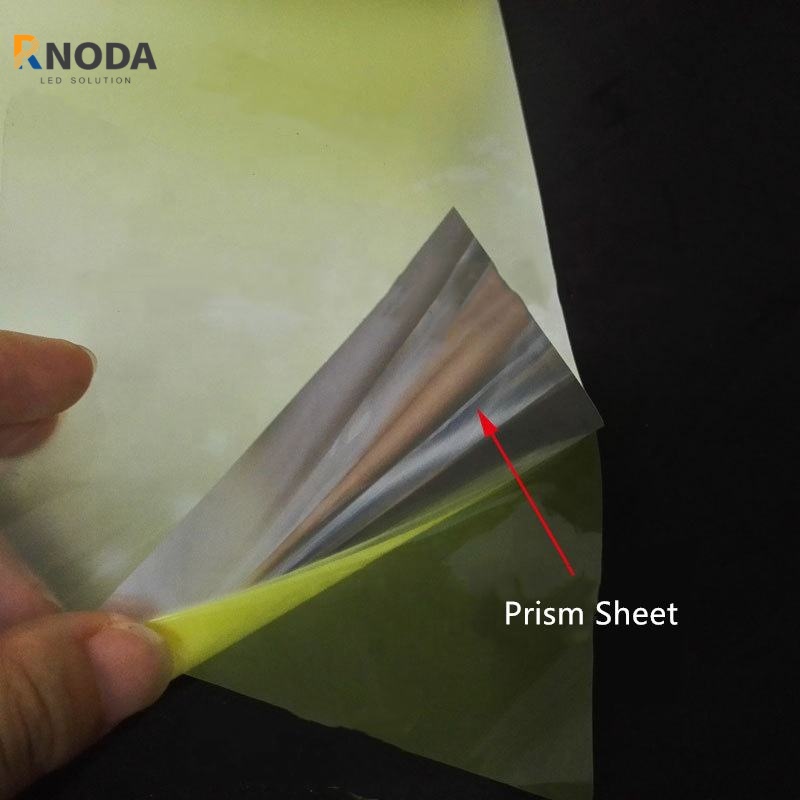

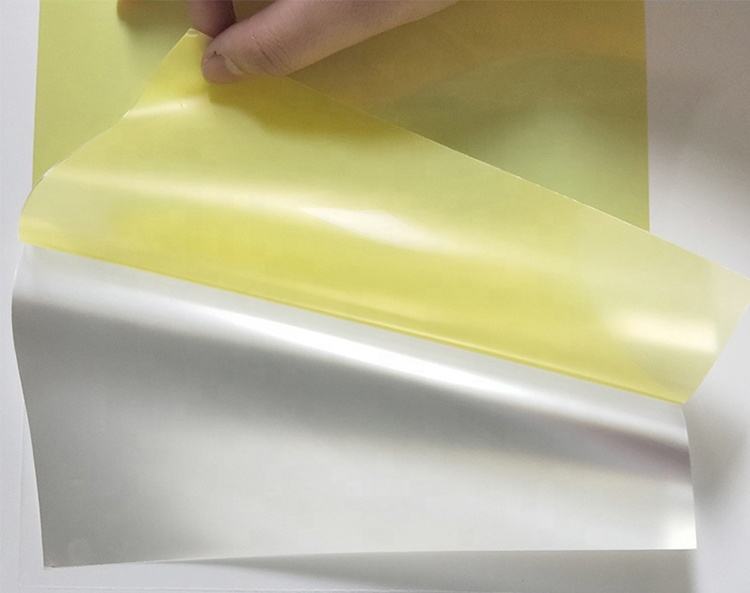

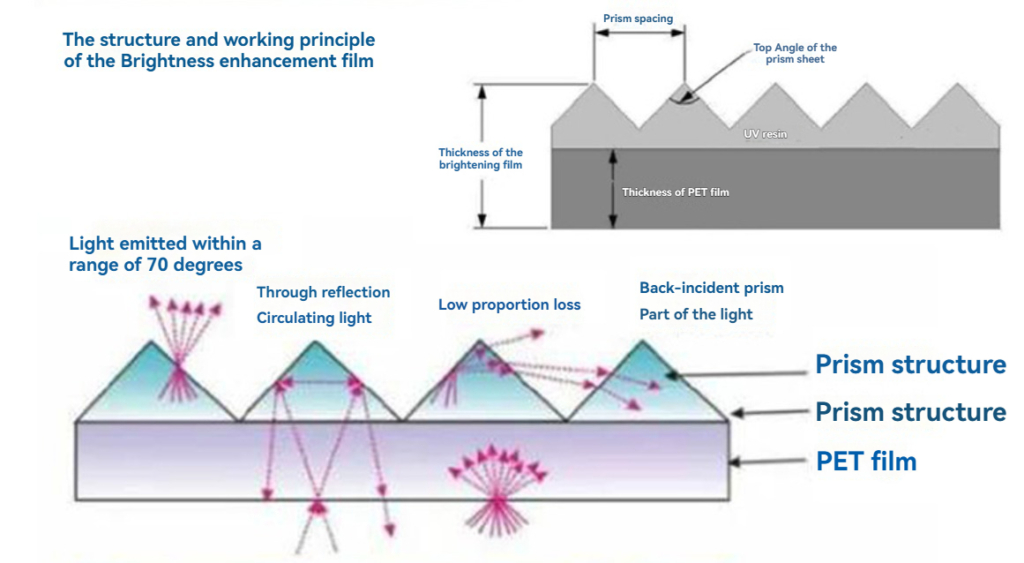

laptop Prism film: Also known as prism sheet, brightness enhancement film, or BEF, this is an optical film made by precisely forming a uniform prism pattern on the surface of highly transparent PET using acrylic resin. When assembled in front of the backlight, it focuses the light emitted by the light source toward the user of the display device, thereby increasing the brightness of the front surface (when two pieces are used orthogonally, a vertical BEF pattern is formed). Additionally, light that is not utilized outside the viewing angle is recycled through the re-reflection effect of light and gathered at an appropriate angle toward the user, achieving a brightness-enhancing effect.

Prism film working Principle

| Product name | Laptop Prism film for lcd application |

| Material | PET |

| Size | 14inch ,15.6inch,17.3inch etc. can be customized |

| Thickness | 0.115MM0.21MM.0.275MM |

| Optical grade | Quality A |

| Degree/angle | 0 /90 /45/135 Degree |

| Application | LCD backlight;led lighting fixture;automotive display |

| Origin | China,Guangdong province |

There are some standard size of prism film for LCD as below :

| Prism film Standard size | Exact size |

| 13.3inch | 298*170MM |

| 14inch | 315*180MM |

| 15.6inch | 349*199MM |

| 17.3 | 387*220MM |

If you require customized size, you can contact us to confirm the size ,degree and quantity for quotation.

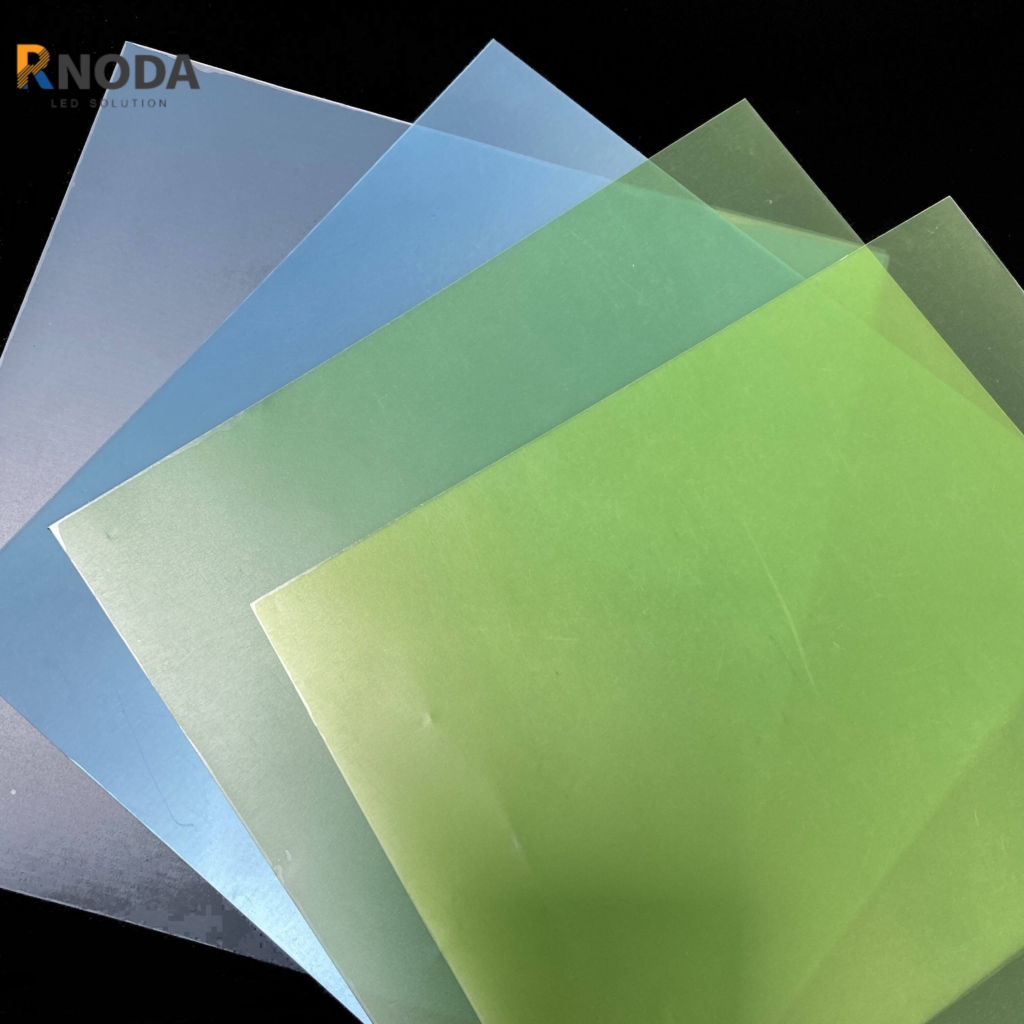

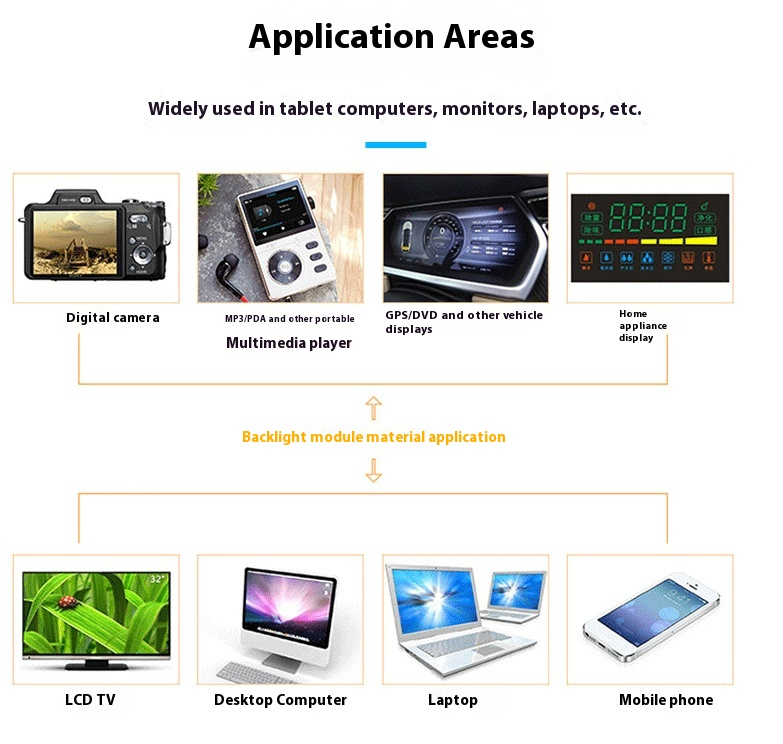

prism film Applications:

- Consumer Electronics: Widely used in laptops, LCD monitors, LCD TVs, color screen mobile phones, digital cameras, and digital video equipment to enhance screen brightness and visual effects.

- Automotive Electronics: Used in automotive navigation systems, etc., to enhance display clarity and adapt to complex lighting conditions.

- Portable Devices: Such as portable DVD players, etc., to optimize display performance.

Usage Notes:

The Prism film must be installed correctly ( two layers overlapped at right angles) to achieve optimal performance.

During production, parameters such as angle and cleanliness must be strictly controlled to prevent issues like scratches or foreign object adhesion caused by handling or manufacturing process problems.

Customized Backlight Solutions & Optical Sheets Supplier – Rnoda Tech

Customized Backlight Solutions & Optical Sheets Supplier – Rnoda Tech