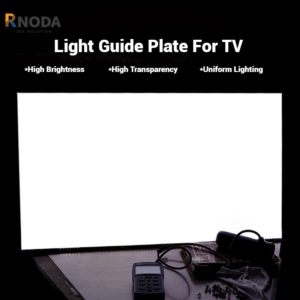

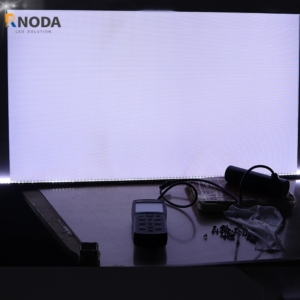

Our precision-engineered light guide plates deliver high brightness and uniform illumination for medical LED X-Ray Viewers. Designed for X-ray and CT image clarity, ideal for OEMs and medical display manufacturers.

Product Specifications

| Product name | High-Uniformity Light Guide Plate for Medical Film Viewers |

| Thickness | 3MM,4MM,6MM,8MM,10MM |

| Custom size avaliable | YES |

| Density | 1.2 g/cm3 |

| Application | A Grade, can be used for lighting,Medical film viewers, X-ray light boxes |

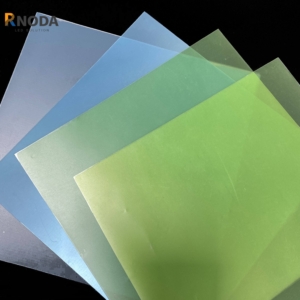

| Material | PMMA, PS,MS |

| MOQ | 100 Pieces |

| Packaging | PE film or Kraft Paper on both sides, wooden pallet |

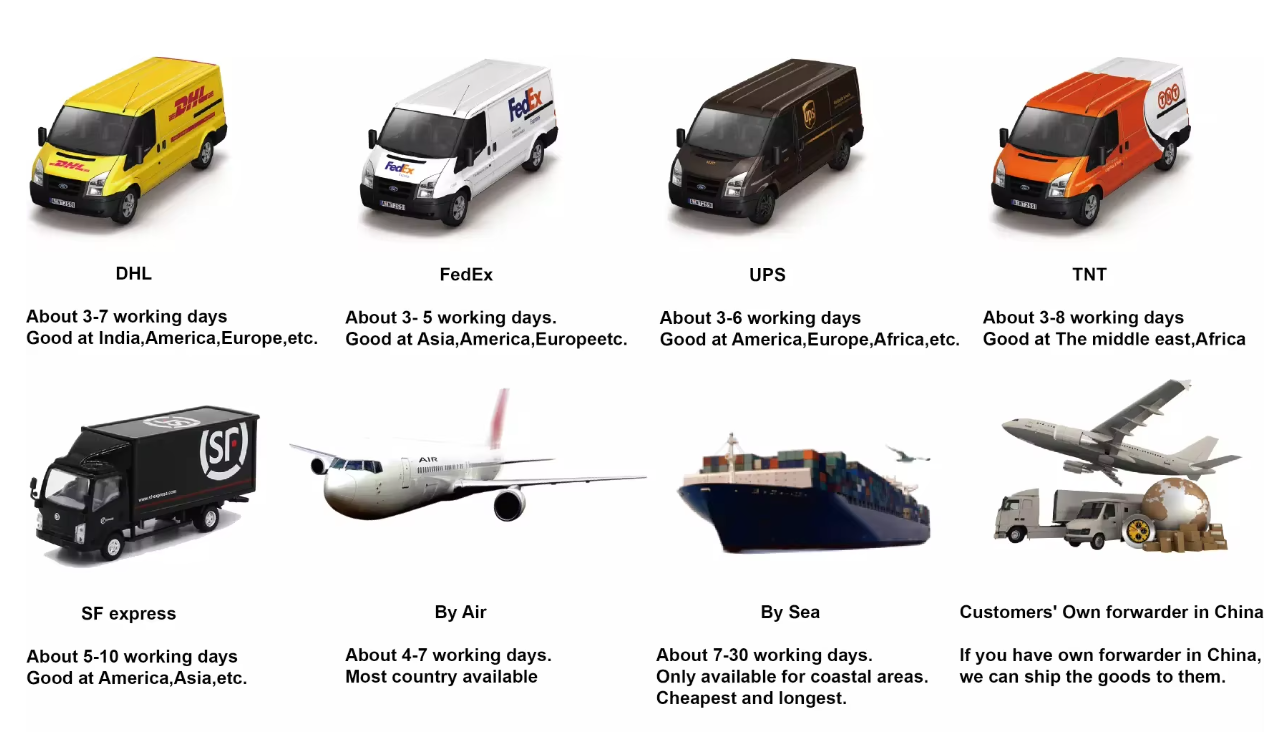

| Delivery time | 7-15 days( According to your needs and custom size) |

Key Features & Benefits

- 🔹 Ultra-high Uniformity – No dark spots, ensuring accurate image viewing

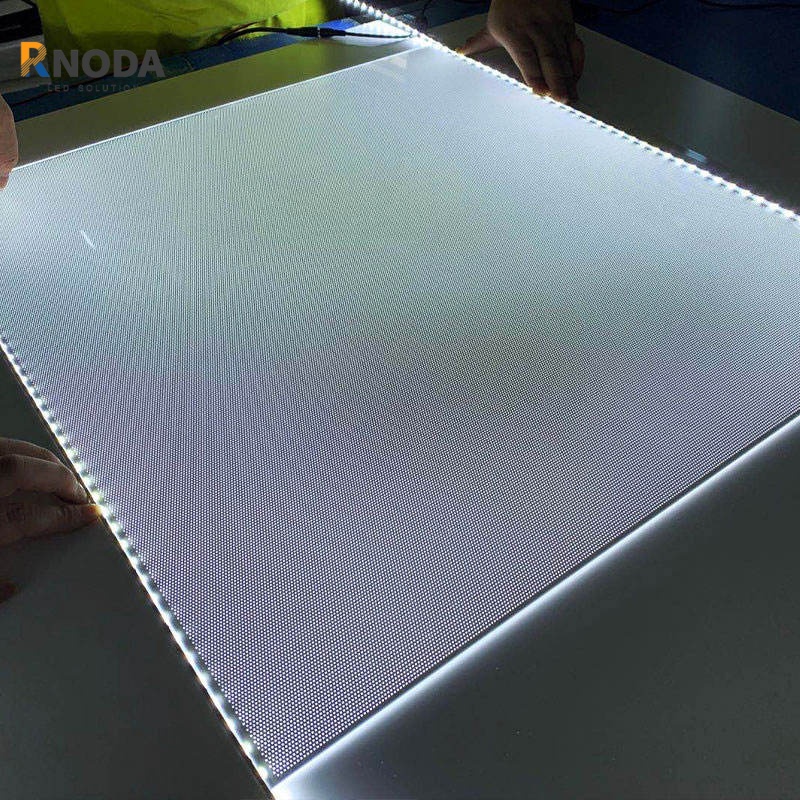

- 🔹 Optimized for LED Edge Lighting – Enhances brightness with low power

- 🔹 Medical-grade PMMA – Excellent light transmission and durability

- 🔹 Customizable Sizes & Dot Patterns – Meet different viewer designs

- 🔹 Thin & Lightweight – Easy to assemble in compact medical equipment

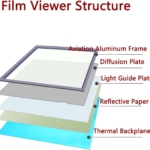

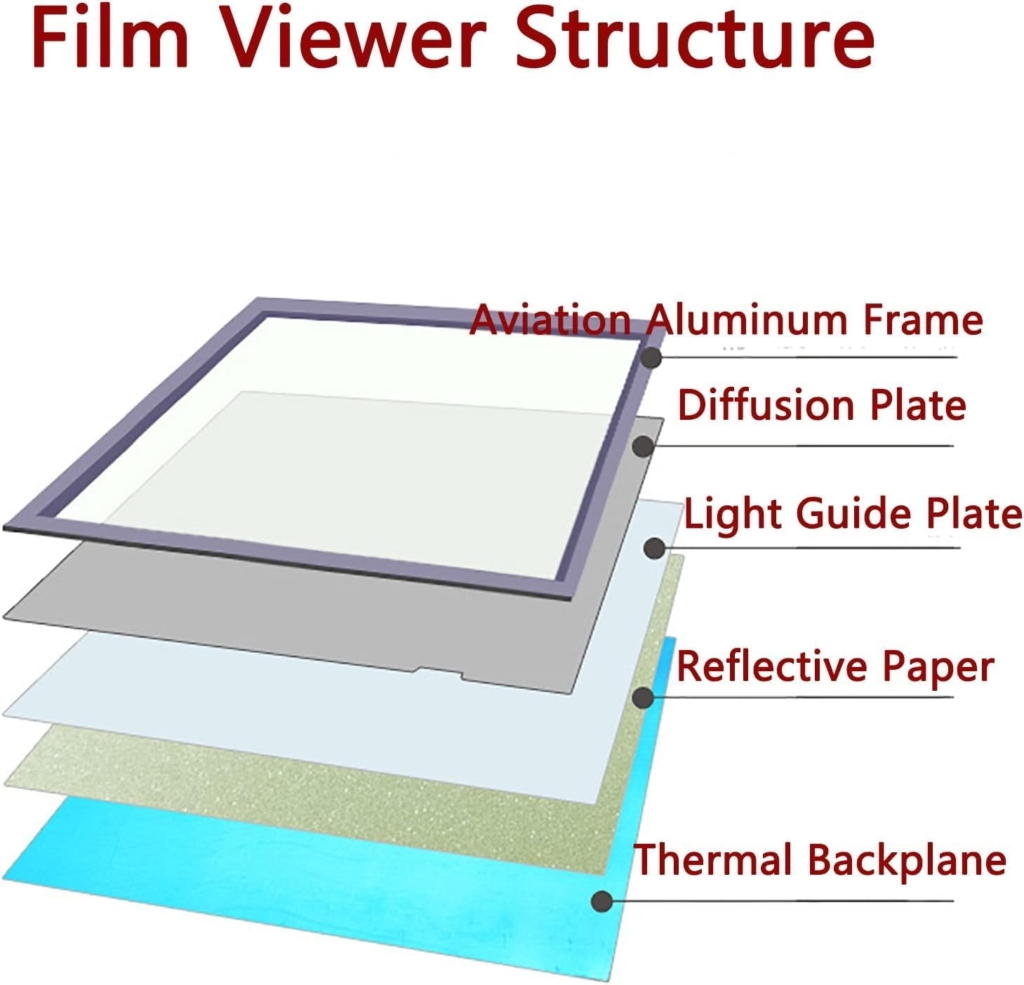

Medical film viewer Structure

1.Aviation Aluminum Frame

High-strength aviation-grade aluminum frame, lightweight and sturdy, protects the overall structure and secures the panel.

2.Diffusion Plate

Used to evenly scatter the light emitted by the light guide plate, eliminating local bright spots and providing soft, consistent backlighting.

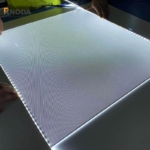

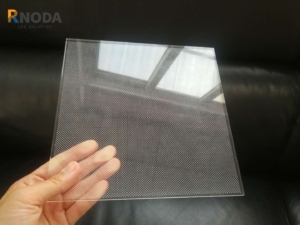

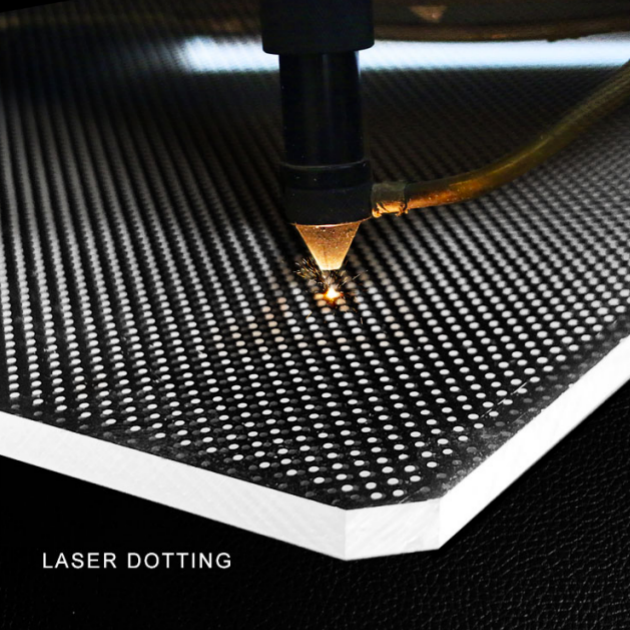

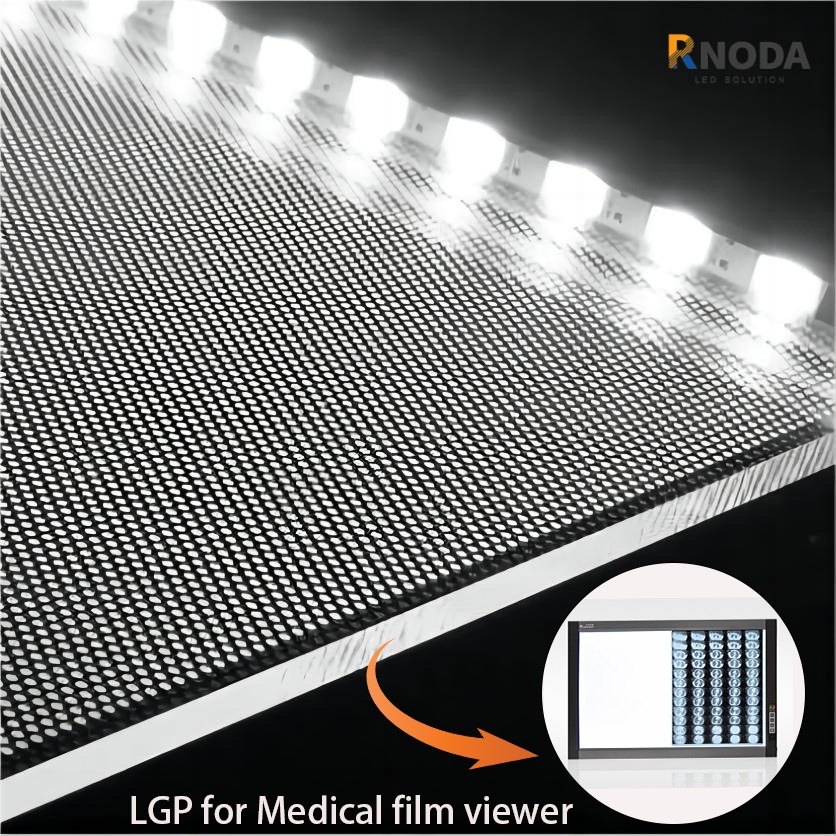

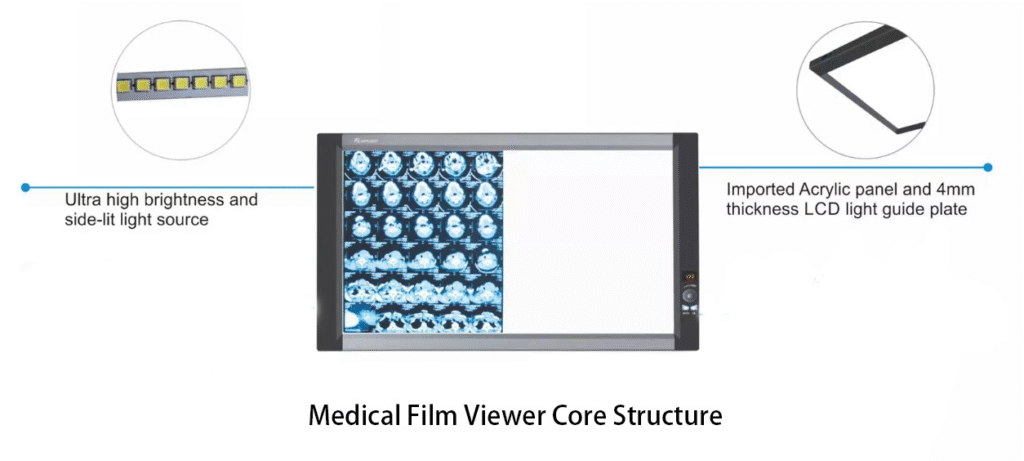

3.Light Guide Plate

Made from high-transparency PMMA or PS material, with LED light sources injected along the edges. Light is uniformly emitted through laser dot matrix or V-cut structures, creating a bright and even illuminated surface.

4.Reflective Paper

Located beneath the light guide plate, it reflects unused light back into the system, enhancing brightness and light efficiency.

5.Thermal Backplane (Heat Dissipation Backplate)

Provides an efficient heat conduction path to assist in cooling the LEDs and the entire system, extending service life and ensuring stable operation.

6.LED Side Light Source

Side-emitting LED light strips installed along the edges, illuminating the edges of the light guide plate and entering the internal light path system

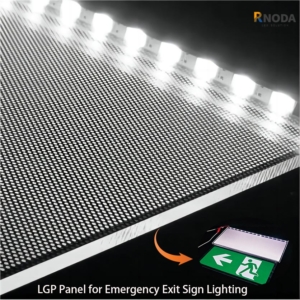

Light Guide Plate Applications in LED X-Ray Viewers

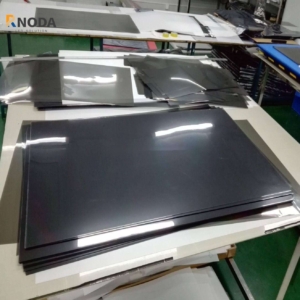

Factory Workshop

Customized Backlight Solutions & Optical Sheets Supplier – Rnoda Tech

Customized Backlight Solutions & Optical Sheets Supplier – Rnoda Tech