What is a Reflective Film?

Reflective films are one of the core optical materials in LCD backlight modules. Positioned beneath the light guide plate (LGP), they form the bottom layer of the backlight assembly. Their primary function is to reflect light leaked from the LGP back toward the display panel, thereby reducing light energy loss and enhancing overall brightness and display uniformity.

Reflector films are widely used in various LCD backlight modules, including smartphones, laptops, monitors, industrial control screens, and large-screen televisions. They effectively enhance brightness uniformity, improve light energy utilization, and help reduce power consumption across different application scenarios.

Main Types of Reflective Films

1. White Reflective Film

Material: Primarily PET (polyester) and PP (polypropylene), with PET reflector film accounting for over 99.8% of the market share.

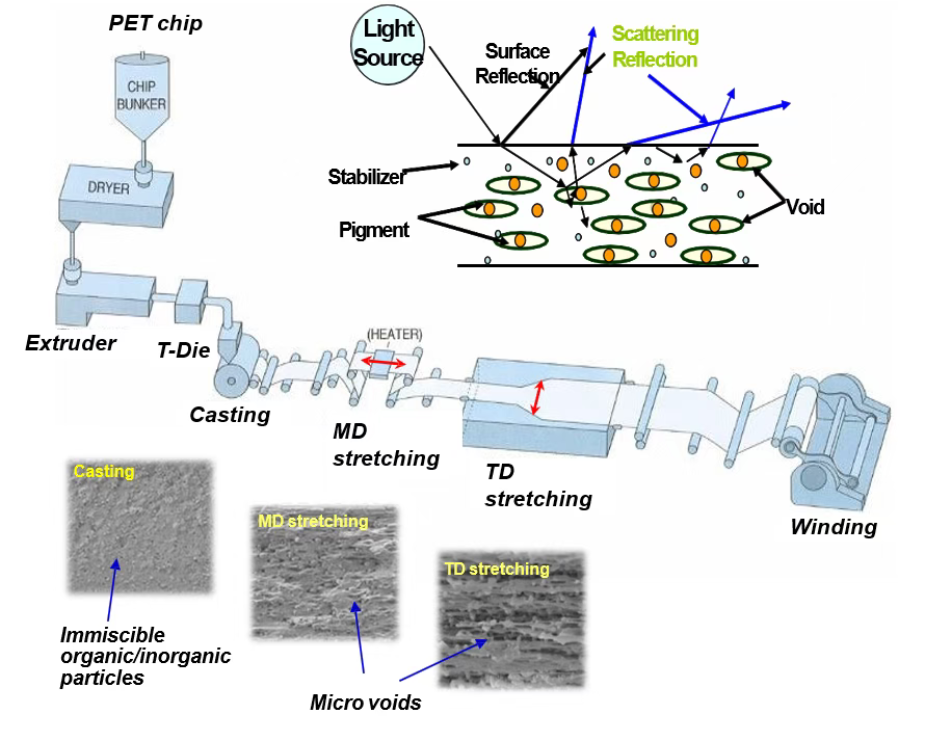

Principle: Incorporating incompatible resins or particles into the PET substrate, followed by biaxial stretching to form a uniform microporous structure, achieving high reflectivity.

Reflectivity: ≥96%, which can be enhanced to 97–100% through surface coating or plating treatments.

Applications: Primarily used in mid-sized backlight modules for tablets, laptops, and automotive displays, also suitable for TV reflector films and industrial monitors.

Major Manufacturers: Changyang, Dongxucheng, Mitsubishi, Lanpucheng, Jizhi, Teijin, SKC, etc.

2. Metal Reflective Film (Mirror Reflective Film)

Process: Deposits silver or aluminum onto polymer film surfaces to form highly conductive metal layers.

Reflectivity: Exceeds 99%, with negligible light energy loss.

Drawbacks: High cost, price-sensitive.

Applications: Primarily used in small-to-medium backlight modules for smartphones, tablets, and laptops; less common in large-screen televisions.

3. ESR High-Brightness Reflective Film (Enhanced Specular Reflector)

Overview: ESR is a high-efficiency multilayer optical reflective film developed by 3M, hailed as the “gold standard” for small-sized high-brightness backlight modules. It delivers exceptional reflectivity, “often imitated but never surpassed.”

Market Trends: In recent years, ESR’s market share has declined annually due to improved reflectivity in other films, increased transmittance in TFT-LCD panels, enhanced gain in light-enhancing films, and brighter light guides.

Structural Features: Composed of multiple nanoscale polymer layers, with thickness varying by layer count. Primary models for small-sized backlight modules are ESR-65 (65μm thick) and ESR-80V2 (80μm thick), with ESR-80V2 being the predominant type.

Reflection Principle: Approximately 1,000 layers of polymer materials are composite-structured, with each layer specifically designed to reflect light of a particular wavelength. The film contains no metals and is non-conductive. Within the visible spectrum (380–780 nm), reflectivity exceeds 98%. Reflectivity is nearly identical on both sides, eliminating orientation requirements during cutting and assembly.

Application Advantages: Ideal for small-sized high-brightness backlight modules in mobile phones, tablets, laptops, etc., delivering exceptional brightness and uniform illumination.

Reflective sheet Structure and Manufacturing Technology

Different Structural Designs

Single-layer structure: Enhances opacity by adding inorganic fillers but offers relatively low reflectivity, suitable for entry-level applications.

Three-layer structure: Core layer uses low-density olefin or foamed material; surface layer employs pure polyester or polyester with optimized inorganic particles, significantly boosting reflectivity and optical performance. Ideal for TV reflective films and large-size displays.

Key Manufacturing Processes

Biaxially Oriented Polyester Film Production Line: Core equipment for manufacturing white PET reflective films.

Coating/Lamination Treatment: Further enhances reflectivity to near 100%.

Heat Dissipation Coating Technology: Applies a roughened coating to the reflective film surface, increasing the air layer’s capacity to improve LED backlight heat dissipation and extend display lifespan.

Conclusion

Reflective sheet are critical materials for LCD and TV backlight modules, directly impacting display brightness, energy efficiency, and lifespan. Future industry trends include:

Higher reflectivity (approaching 100%);

Lower costs and scaled production;

Functional designs integrating thermal management capabilities.

White reflective films, PET reflective films, TV reflective films, and ESR high-brightness reflective films will continue playing vital roles in the global display industry.

Customized Backlight Solutions & Optical Sheets Supplier – Rnoda Tech

Customized Backlight Solutions & Optical Sheets Supplier – Rnoda Tech